Potato Chips Machine

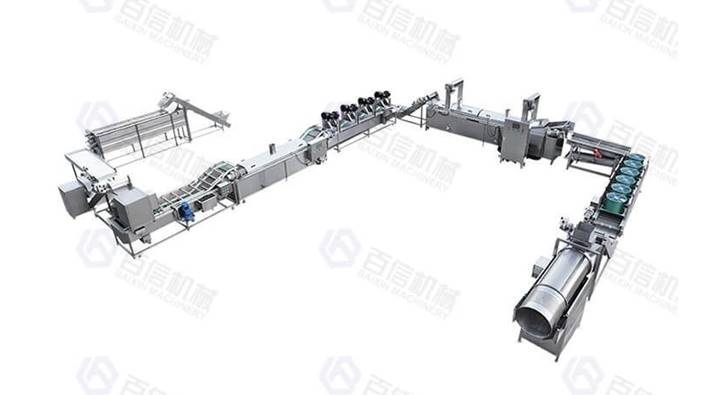

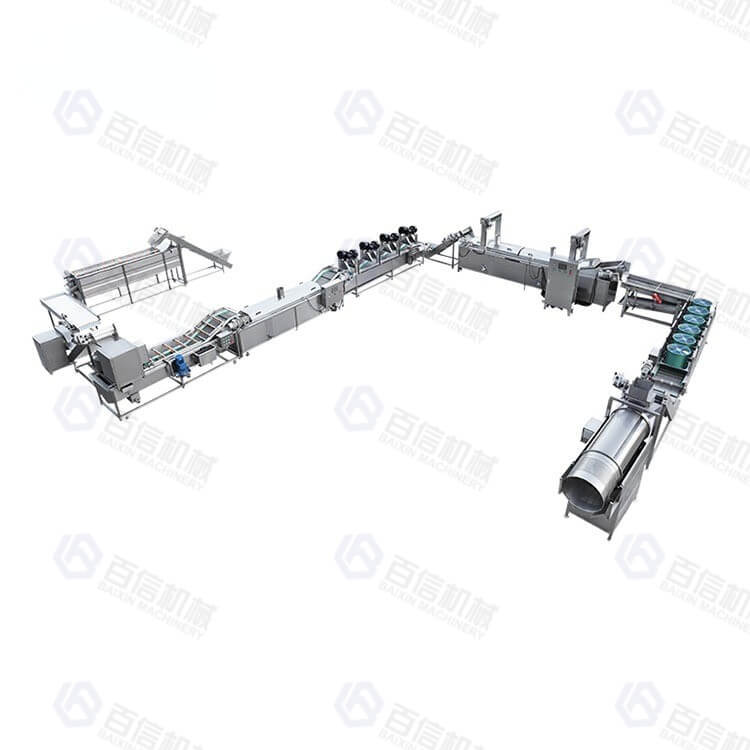

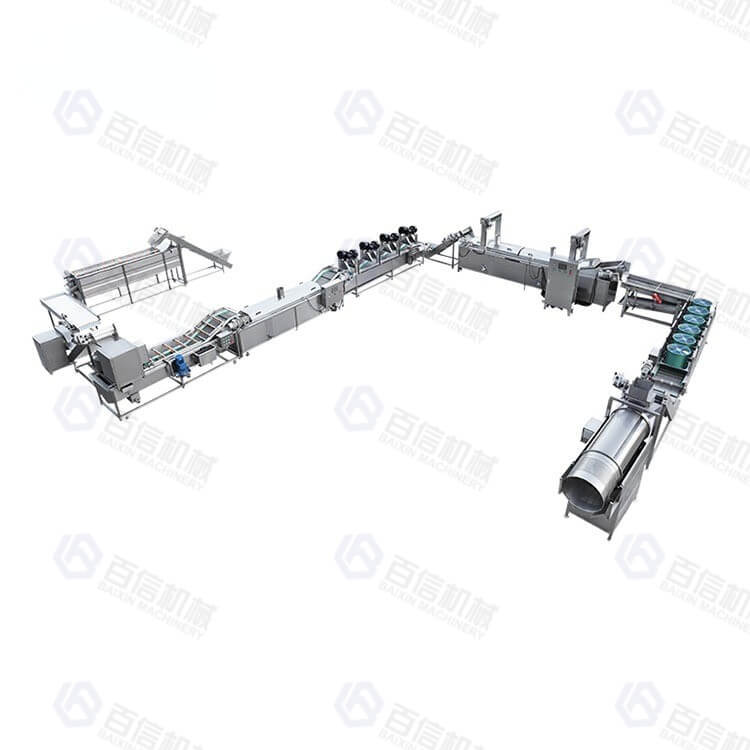

Potato Chip Machine and Technology Flow

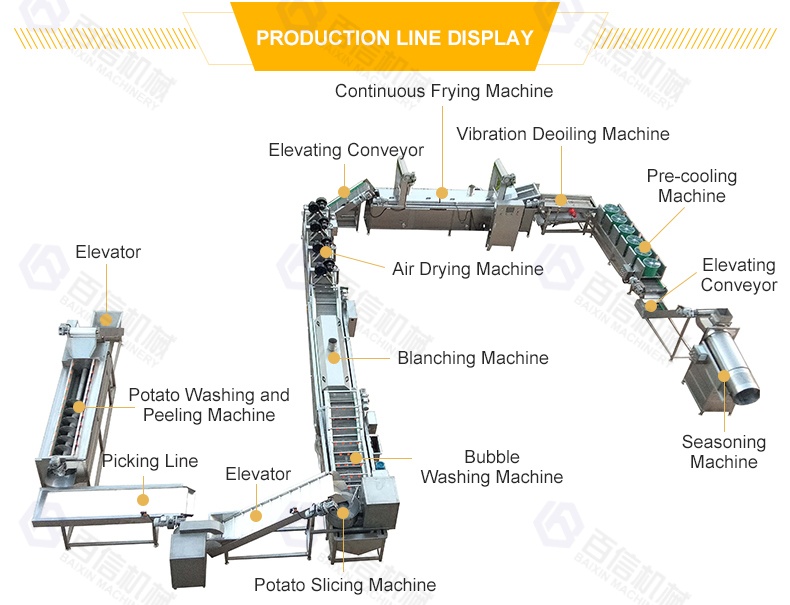

The potato chips machine is an automated processing system integrating potato washing and peeling, slicing, blanching, frying, seasoning, and packaging. It realizes automation of the potato chips production process, greatly improves production efficiency, and ensures consistency in taste and appearance. Whether you plan to open a small potato chips workshop or build a fully automated large production line, a suitable potato chips processing machine can significantly improve efficiency, reduce costs, and enhance market competitiveness. This article will comprehensively introduce the processing flow, equipment configuration, and purchasing guidelines of potato chips machines to help customers quickly understand suitable production line solutions.

A complete set of potato chips machines mainly includes the following core equipment:

| No. | Machine Name | Advantage |

| 1 | Elevator | 1. The size can be customized

2. Conveying speed adjustable. |

| 2 | Potato Washing and Peeling Machine | 1. Washing and peeling capacity can be customized.

2. The length of brush can be customized. 3. We use high quality brusher, even old potatoes that are hard to peel can be peeled well. 4. Spraying system to clean the potatoes. 5. Spiral design to make sure automatic discharging. 6. The discharge speed can be adjusted. 7. The whole machine is made of 304 stainless steel. |

| 3 | Picking Line | 1. Picking table size can be customized.

2. Conveying speed adjustable. |

| 4 | Elevating | 1. The size can be customized.

2. Conveying speed adjustable. |

| 5 | Potato Slicing Machine | 1. Potato chips thickness 1–5 mm can be adjustable.

2. Cutting surface is smooth without damage. |

| 6 | Bubble Washing Machine | 1. Remove the starch from the potato chips.

2. Strong water flow, bubble impact. 3. High pressure spraying system.4. Filter system and water recycling system. |

| 7 | Blanching Machine | 1. You can use gas, electricity or diesel as power for this machine depending on your needs.

2. It can effectively protect original vivid color of the potato strips/potato chips.3. You can add additives during blanching process. |

| 8 | Vibration Dewatering Machine | The de-water time is adjustable. |

| 9 | Air Drying Machine | 1. The multi-layer mesh belt conveyor belt and special fan outlet completely remove the moisture on the surface of the potato slices.

2. Fan can be adjusted up and down. |

| 10 | Elevating Conveyor | 1. The size can be customized.2. Conveying speed adjustable. |

| 11 | Continuous Frying Machine | 1. Automatic lifting system, easy to clean.

2. Double mesh belt transmission to avoid the chips floating. 3. Oil filter and recycling system to automatically and continuously filter the oil residue to extend the service life.4. Electric or gas heating. |

| 12 | Vibration Deoiling Machine | The de-oil time is adjustable. |

| 13 | Pre-cooling Machine | 1. The multi-layer mesh belt conveyor belt and special fan outlet completely remove the oil on the surface of the potato slices.

2. Fan can be adjusted up and down. |

| 14 | Elevating Conveyor | 1. The size can be customized.

2. Conveying speed adjustable. |

| 15 | Seasoning Machine | 1. With spice tank, the flow of spice adjustable.

2. You can add additives any you want even liquid such as oil, water etc. 3. Seasoning time can be controlled. |

| 16 | Automatic Weighing Packing Machine | It can fill nitrogen automatically, automatic weighing, automatic sealing and automatic packing. |

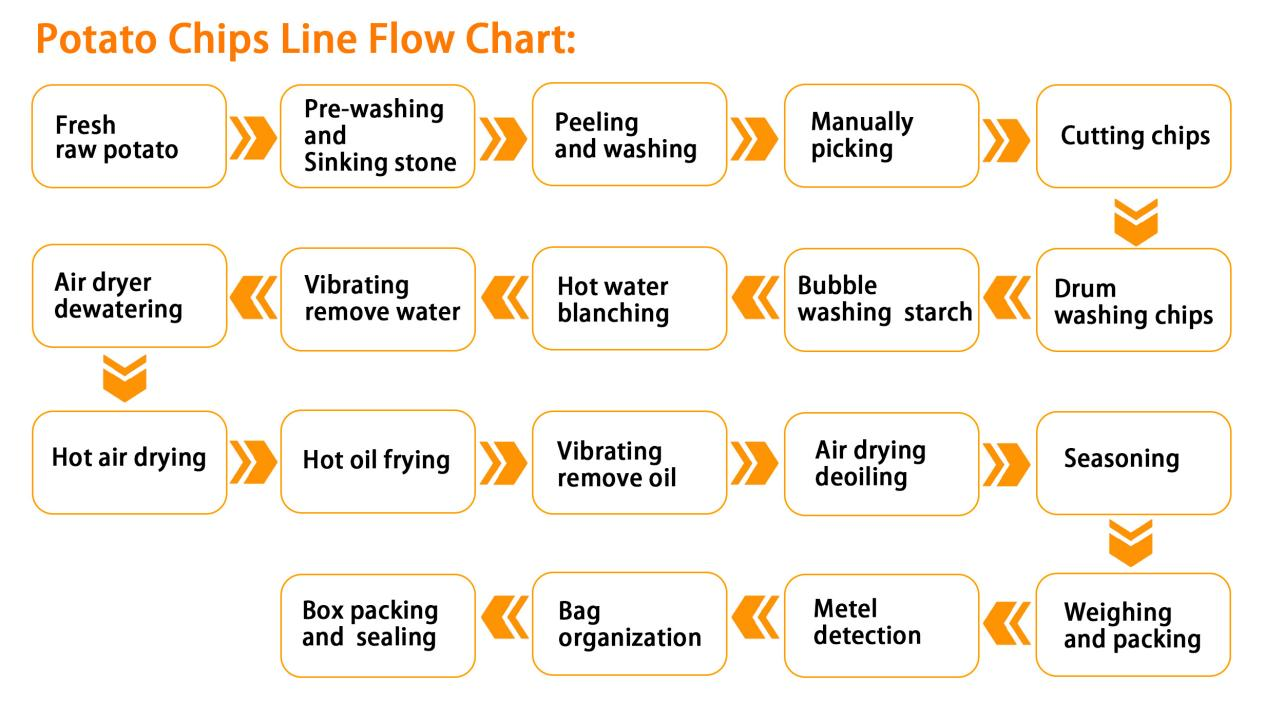

To produce crispy potato chips with stable quality, standardized processing procedures are indispensable. The potato chips processing flow is as follows:

Fresh raw potato—Pre-washing and sinking stone—Peeling and washing—Manually picking —Cutting chips—Drum washing chips—Bubble washing starch—Hot water blanching—Vibrating remove water—Air dryer dewatering—Hot air drying—Hot oil frying—Vibrating remove oil—Air drying deoiling—Seasoning—Weighing and packing—Metal detection—Bag organization—Box packing and sealing

Raw Material Requirements and Finished Product Standards

To ensure stable quality and excellent taste of the processed potato chips while improving yield rate and quality consistency, strict control must be applied to both raw potato selection and finished product standards. Below are the raw material requirements for potatoes suitable for chip processing and the core quality indicators for finished chips, serving as reference for production preparation and procurement:

(1) Requirements for Raw Potatoes

Variety characteristics: Priority should be given to varieties with white flesh and low fiber content; avoid varieties with yellow flesh or spots.

Shape and size: Tubers should be small and round, with a diameter of about 60 mm, which facilitates uniform slicing and reduces raw material waste.

Composition indicators: Starch content 12%–15% (too high may cause burning during frying, too low leads to a soft texture); reducing sugar ≤ 0.3% (to avoid overly dark color after frying).

(2) Finished Potato Chips Quality Standards

Appearance: Uniform golden color, intact slices.

Texture: Crispy when eaten, no sogginess, no burnt smell, no astringent taste.

Oil content: 28%–32% (slight variation depending on variety and process); reducing sugar ≤ 0.25%.

Because potato chip production lines vary significantly in core configuration, number of equipment, and level of automation, their overall investment costs fluctuate considerably depending on the processing capacity. To help processors of different sizes make precise selections based on their needs, Baixin will provide a detailed analysis of Ethiopian potato chip machine prices and suitable market positioning for small, medium, and large processing capacities, helping investors make informed choices based on their capacity and budget.

Guide to Selecting Potato Chips Machine

Understanding equipment configuration, processing flow, and raw material and product standards is the first step in starting a potato chips processing business. To ensure smooth commissioning and operation of the production line, choosing suitable potato chips machines is crucial. Machines of different capacities vary significantly in automation level, cost, energy consumption, and plant requirements. Therefore, before official production, it is necessary to understand the key purchasing points to ensure stable operation and expected output. Next, Baixin Machinery will explain in detail from the perspectives of configuration selection, budget matching, and plant conditions.

1.Small Capacity (50 kg/h)

Features: Adopts a “semi-automatic + manual assistance” production mode. Compact structure and low investment threshold, suitable for startups, small food workshops, or trial production of specialty-flavored chips. It features low investment cost and easy operation.

Configuration: Washing and peeling machine – slicer – blanching machine – dewatering machine – manual fryer – deoiling machine – seasoning machine – packaging machine.

Production condition requirements:

Water consumption: 300–500 L per shift

Power consumption: 100–150 kW per shift (depending on heat source)

Floor area: about 100–150 m²

Machine cost: about USD 40,000–60,000.

Labor requirement: 3–5 people.

Basic production conditions include suitable power supply, stable and sufficient water source, reasonable drainage, flat and non-slip floor easy to clean, and reserved space for operation and maintenance.

2.Medium Capacity (100–200 kg/h)

Features: Upgraded automation level, realizing continuous operation of key processes such as slicing, frying, and seasoning, reducing manual intervention. Suitable for medium-sized food factories.

Configuration: Water Bucket elevator – screw washing and peeling machine – picking table – cutting machine – bucket elevator – blanching machine – vibrating dewatering machine – hot-air dryer – frying machine – vibrating deoiling machine – seasoning machine – packing machine.

Production condition requirements

Medium-sized potato chips machine have certain requirements for production conditions: the factory needs to be equipped with a stable power supply and sufficient water supply to support continuous production, meet the water needs of multiple equipment operating simultaneously and processes such as cleaning and blanching, and at the same time, it needs to have a complete drainage and smoke purification system that meets environmental protection and production hygiene standards. The ground needs to be hardened and non-slip, and sufficient space should be reserved for the layout of production lines and operating passages.

Machine cost: about USD 120,000–200,000.

Water consumption per shift: about 1,500–3,500 L

Power consumption per shift: 400–500 kW (depending on heat source)

Floor area: 350–1,000 m².

Labor requirement: 2–4people.

3.Large-scale capacity (300kg/h)

Features: Fully automated and large-scale production, supports 24-hour continuous operation, equipped with automatic oil filtration and refilling systems, reducing oil loss and energy costs. Large-scale production lowers unit cost and enhances market competitiveness. Suitable for large food enterprises and chain snack brands.

Configuration:Includes material silo, drum washing machine, potato sorter, bucket elevator, screw washing and peeling machine, high-efficiency slicer, continuous blanching and cooling system, continuous fryer, as well as supporting oil filling machine, oil filter, oil storage tank, seasoning machine, and automatic weighing and packing machine.

Production condition requirements:

Requires about 1,000–1,500 m² of plant space for reasonable division of raw material area, processing area, frying area, packaging area, and finished product storage, ensuring clear material flow and food safety compliance. Requires stable industrial power supply for continuous fryers, blanching lines, air-cooling systems, and automatic packaging machines. Strong dependence on water supply for washing, blanching, and cooling, with drainage systems. Frying area must be equipped with professional fume exhaust and ventilation systems. Floors must be hardened, non-slip, and waterproof.

Machine cost: about USD 200,000–400,000.

Water consumption per shift: about 2,500–5,500 L

Power consumption: 800–1,300 kW (depending on heat source).

Besides capacity and budget, three major factors must also be considered:

Equipment material: Parts in contact with food must be made of 304 stainless steel (corrosion-resistant, easy to clean, and compliant with food safety standards). Avoid ordinary carbon steel (prone to rust and food contamination).

Process adaptability: For multi-flavor production, confirm whether the seasoning system supports multi-channel simultaneous operation.

After-sales service: Give priority to suppliers who provide installation and commissioning, operation training, and regular maintenance to avoid production interruption due to equipment failure.

The Strength of Potato Chips Machine Manufacturers

For investors, equipment procurement is only the first step; subsequent installation, transportation, and warranty services directly impact the production line's commissioning and long-term stable operation. Baixin Machinery has established a standardized service system based on the concept of "full-cycle service."

1.Installation and Technical Training

Baixin Machinery boasts a professional installation team with extensive experience. For projects requiring on-site installation, Baixin Machinery will dispatch a team of highly experienced engineers to the customer's factory for equipment installation. After installation, they will conduct full-process trial runs and debugging to ensure the stable and efficient operation of the entire production line. Simultaneously, engineers will provide systematic usage and maintenance training to the customer's operators, helping the factory quickly transition to normal production.

|

Install Details |

|

|

1 |

Our company attaches great importance to installation. We have our own installation team. The number of installation personnel has grown from the initial 3 to a current team of 10, and we are still training more people. |

|

2 |

The majority of our equipment upgrades come from the installation site. This is the core aspect through which we ensure the equipment is up-to-date and employs the latest processing techniques. |

|

3 |

Our installation team has installation experience in over 20 countries. Our company encourages business personnel to participate in the on-site installation together with the installation team, providing more professional and high-quality after-sales service. |

|

4 |

After each installation site is completed, our after-sales department, technical department, production department and business department will organize special seminars to ensure that our after-sales service capabilities and equipment quality keep improving. |

|

5 |

After the equipment is delivered, we will provide a list of installation tools that need to be prepared on-site, a material list, and other necessary preparations. |

|

6 |

During the on-site installation process, we will provide training services, including operation of the production line and daily maintenance. |

2.Safe and Fast Transportation

Based on years of experience in equipment export, Baixin Machinery has established a fully controllable transportation process, as shown in the diagram below.

|

Delivery Steps |

|

|

1 |

The production department, the after-sales department and the business department will check the delivery list one by one to ensure that no details are missed. |

|

2 |

Equipment container planning, providing the most optimal container arrangement plan to ensure the safety of equipment loading, with the minimum number of containers required. |

|

3 |

Establish an order delivery group, and assign a specific person for each batch of goods. Conduct a re-count of the equipment. |

|

4 |

During the shipping process, photos of each device and component are taken for record-keeping. |

|

5 |

After the goods are dispatched, provide the customers with detailed and accurate packing information to make the receiving process as smooth as possible for them. |

|

6 |

During the shipping process, photos of each device and component are taken for record-keeping. |

3.Comprehensive Warranty and After-sales

Baixin Machinery provides a one-year warranty for all its potato chip processing machine and maintains a 24/7 online response mechanism throughout the production line operation to ensure timely handling of equipment malfunctions. If the equipment malfunctions due to its own quality or process defects, we will provide free repair services or directly replace the faulty parts/equipment within 7 days of purchase, minimizing the impact on production.

|

Warranty |

|

|

12 months |

Seller warrants that the Equipment supplied shall be new and shall be free from defects in materials and workmanship for period of 12 months from the date of commissioning and handover of the complete working plant by Seller to Buyer the "Warranty Period"). |

|

7days |

Seller's warranty covers the following:Defects in materials and workmanship of the Equipment.Any defective parts (due to defects in materials and workmanship during the warranty shall be repaired /replaced free of cost within 7days free of cost. |

|

24h |

During the operation of the production line, if any problems arise, we offer 24-hour online prompt responses. |

In recent years, potato chips, as a high-frequency consumer product, have seen continuous market demand growth, making potato chip machine a popular investment area. Baixin Machinery not only provides standardized potato chip machine of various sizes, but also offers customized solutions tailored to individual customer needs. If you are interested in entering the potato chip processing industry or planning to upgrade your existing production line, please feel free to contact Baixin Machinery! We will assign a dedicated project manager to tailor a complete production plan free of charge, taking into account your production capacity requirements, budget, and site conditions, and provide equipment quotations and return on investment analysis.

-

200kg/h Potato Chips Production LineSee More >

200kg/h Potato Chips Production LineSee More > -

50kg/h Potato Chips Production LineSee More >

50kg/h Potato Chips Production LineSee More > -

Automatic Stirring Batch Potato Chips Fryer MachineSee More >

Automatic Stirring Batch Potato Chips Fryer MachineSee More > -

Full Automatic Potato Chips Production LineSee More >

Full Automatic Potato Chips Production LineSee More > -

Potato Chips Washing MachineSee More >

Potato Chips Washing MachineSee More > -

Semi-Automatic Banana Chips Production LineSee More >

Semi-Automatic Banana Chips Production LineSee More >

1-1.jpg)

2-15.jpg)