Potato Chips Making Machine

With the rapid development of the snack food market, potatochipss have become one of the most frequently consumed snacks, and market demand continues to rise. To ensure stable production, taste, and quality of potatochipss, choosing an efficient potatochipss making machine is crucial. Modern potatochips making machineintegrate potato washing, peeling, slicing, blanching, frying, seasoning, and packing, achieving full automation from raw materials to finished product. This article will comprehensively introduce the potatochips production process, equipment configuration, and key selection points to help customers quickly understand the production line solution suitable for their needs.

Potato Chips Making Machine and Production Process

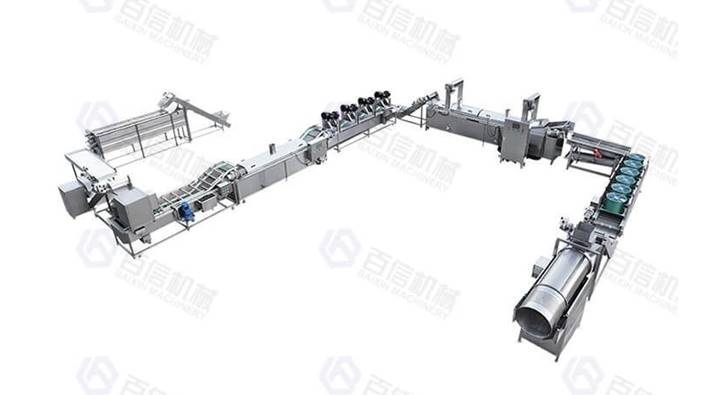

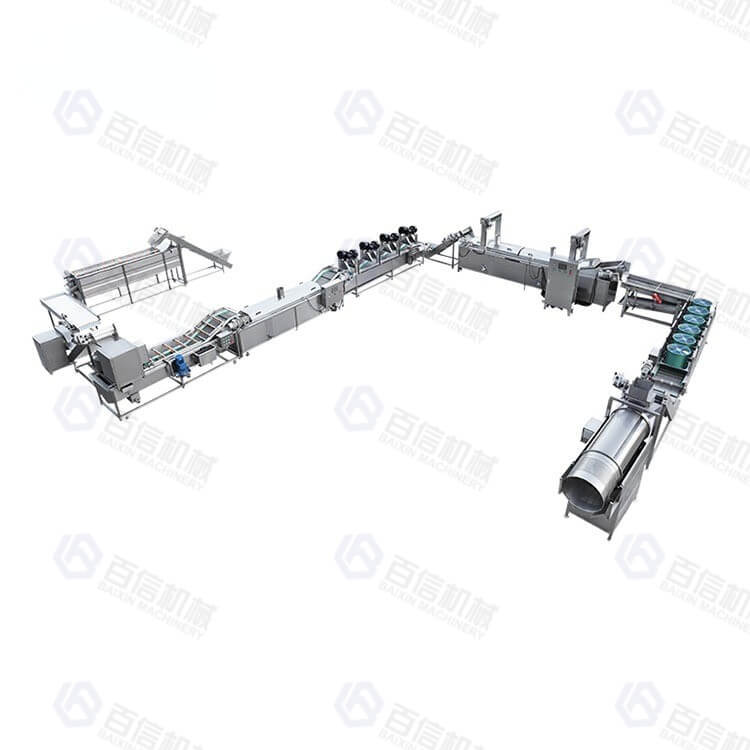

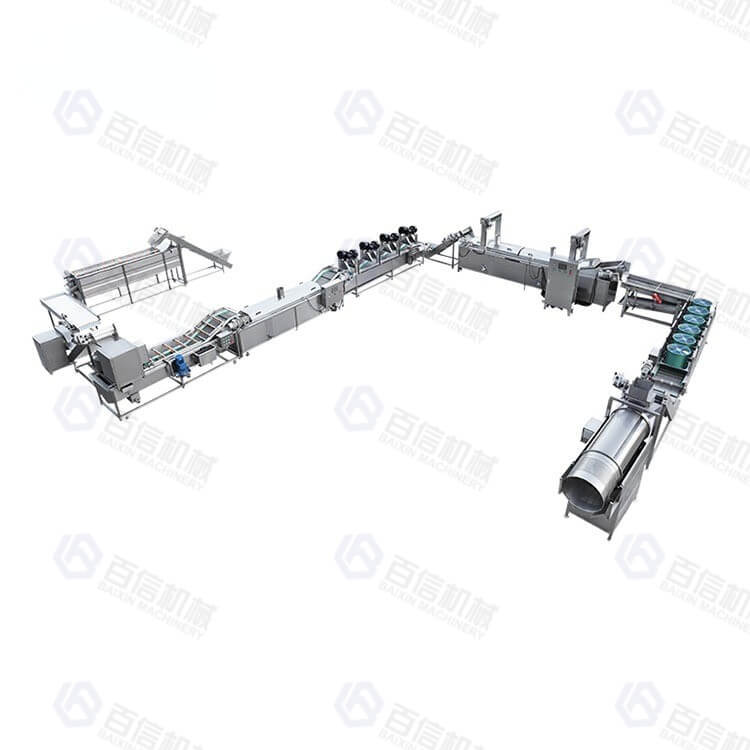

Potato chips making machine typically not single pieces of equipment, but rather a complete, interconnected, and continuously operating production system. To ensure that potatochipss meet consistent standards in terms of taste, appearance, and food safety, the production process involves several key steps, including washing and peeling, slicing, blanching, frying, deoiling, seasoning, and packaging. Each step corresponds to specialized equipment working in tandem. The following detailed introduction to the complete set of equipment required for potato chips making machine will help investors fully understand the composition and function of a complete production line.

| No. | Machine Name | Advantage |

| 1 | Elevator | 1. The size can be customized

2. Conveying speed adjustable. |

| 2 | Potato Washing and Peeling Machine | 1. Washing and peeling capacity can be customized.

2. The length of brush can be customized. 3. We use high quality brusher, even old potatoes that are hard to peel can be peeled well. 4. Spraying system to clean the potatoes. 5. Spiral design to make sure automatic discharging. 6. The discharge speed can be adjusted. 7. The whole machine is made of 304 stainless steel. |

| 3 | Picking Line | 1. Picking table size can be customized.

2. Conveying speed adjustable. |

| 4 | Elevating | 1. The size can be customized.

2. Conveying speed adjustable. |

| 5 | Potato Slicing Machine | 1. Potato chips thickness 1–5 mm can be adjustable.

2. Cutting surface is smooth without damage. |

| 6 | Bubble Washing Machine | 1. Remove the starch from the potato chips.

2. Strong water flow, bubble impact. 3. High pressure spraying system.4. Filter system and water recycling system. |

| 7 | Blanching Machine | 1. You can use gas, electricity or diesel as power for this machine depending on your needs.

2. It can effectively protect original vivid color of the potato strips/potato chips.3. You can add additives during blanching process. |

| 8 | Vibration Dewatering Machine | The de-water time is adjustable. |

| 9 | Air Drying Machine | 1. The multi-layer mesh belt conveyor belt and special fan outlet completely remove the moisture on the surface of the potato slices.

2. Fan can be adjusted up and down. |

| 10 | Elevating Conveyor | 1. The size can be customized.2. Conveying speed adjustable. |

| 11 | Continuous Frying Machine | 1. Automatic lifting system, easy to clean.

2. Double mesh belt transmission to avoid the chips floating. 3. Oil filter and recycling system to automatically and continuously filter the oil residue to extend the service life.4. Electric or gas heating. |

| 12 | Vibration Deoiling Machine | The de-oil time is adjustable. |

| 13 | Pre-cooling Machine | 1. The multi-layer mesh belt conveyor belt and special fan outlet completely remove the oil on the surface of the potato slices.

2. Fan can be adjusted up and down. |

| 14 | Elevating Conveyor | 1. The size can be customized.

2. Conveying speed adjustable. |

| 15 | Seasoning Machine | 1. With spice tank, the flow of spice adjustable.

2. You can add additives any you want even liquid such as oil, water etc. 3. Seasoning time can be controlled. |

| 16 | Automatic Weighing Packing Machine | It can fill nitrogen automatically, automatic weighing, automatic sealing and automatic packing. |

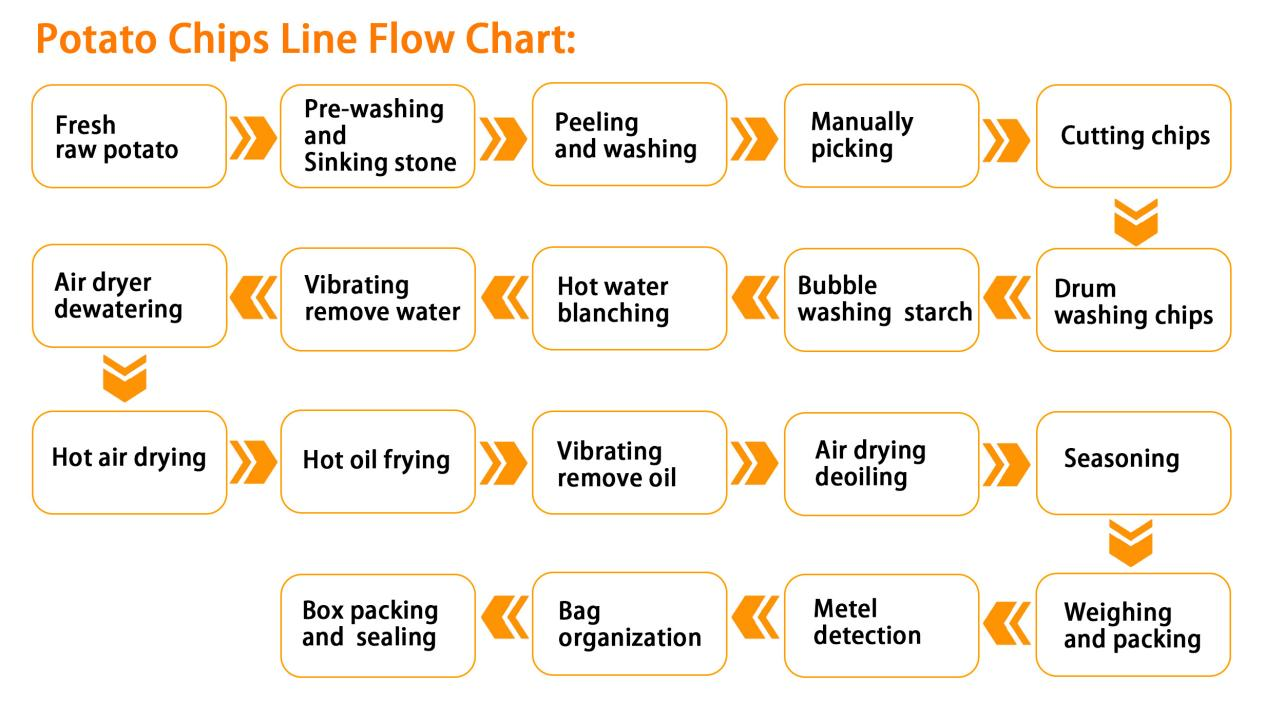

A complete potato chips production process includes the following steps:

Fresh raw potato—Pre-washing and sinking stone—Peeling and washing—Manually picking —Cutting chips—Drum washing chips—Bubble washing starch—Hot water blanching—Vibrating remove water—Air dryer dewatering—Hot air drying—Hot oil frying—Vibrating remove oil—Air drying deoiling—Seasoning—Weighing and packing—Metal detection—Bag organization—Box packing and sealing

Raw Material Requirements and Finished Product Standards

High-quality potato chips rely on premium potato raw materials and strict finished product standards. The stricter the requirements for raw materials and finished products during the production process, the more consistent the taste of the final product and the higher the yield.

(1) Requirements for Raw Potatoes

Variety selection: Choose high-quality varieties with white flesh and less fiber, and avoid potatoes that are yellow or have spots.

Tuber specifications: approximately 60mm in diameter, small and round, which facilitates uniform slicing and reduces production waste.

Ingredient specifications: Starch content between 12% and 15% to ensure golden color and crispiness during frying;

reducing sugar ≤0.3% to prevent potatochipss from burning or becoming too soft.

These indicators not only affect the color and taste of potatochipss, but also relate to the control of oil temperature during frying and the stability of the oil content of the finished product.

(2) Finished Potato Chips Quality Standards

Appearance: The color is golden and uniform, the slices are intact, and there is no obvious breakage.

Texture: Crispy and even in texture, without softening, and without burnt or bitter taste.

Oil content: 28%-32%, which may vary slightly depending on the potatochips variety and processing method;

Reducing sugar ≤0.25%.

Potato Chips Making Machine Selection Plan

Choosing the right potato chips making machine is crucial for ensuring the efficient and stable operation of the production line. Equipment of different capacities and scales varies significantly in terms of automation level, investment cost, energy consumption, and factory conditions. Therefore, before putting the machine into production, it is essential to understand the key selection criteria for potato chips making machine to ensure stable equipment operation and meet expected production capacity requirements.

1.Small-scalePotato Chips Making Machine (50kg/h)

Features: Primarily semi-automated, suitable for startups and small-batch production, with low investment threshold and simple equipment operation. Ideal for entrepreneurs to quickly pilot production, develop unique flavors, or limit small-batch production, while allowing for flexible adjustments to the production process.

Equipment configuration: Washing and peeling machine → Slicing machine → Blanching machine → Dewatering machine → Manual fryer → Deoiling machine → Seasoning machine → Packing machine.

Production conditions: Each batch consumes approximately 300-500L of water , 100-150kw of electricity, occupies approximately 100-150㎡ of land, and requires 3-5 workers. Investment costs are approximately US$40,000-60,000.

2.MediumPotato Chips Making Machine(100-200kg/h)

Features: High level of automation, enabling continuous operation of the production line, saving labor costs, while ensuring production efficiency and product stability.

Suitable for medium-sized factories.

Equipment configuration: Water bucket elevator→ Screw washing and peeling machine → Sorting table → Slicing → Blanching machine → Vibration dewatering → Air drying → Frying → Vibration deoiling → Seasoning → Packing machine.

Production conditions: Requires a stable power supply and sufficient water. The factory floor must be hardened and non-slip, with a complete drainage and smoke extraction system. Each batch consumes 1500-3500L of water and 400-500kW of electricity, occupying 350-1000㎡ of land. Investment cost is approximately US$120,000-200,000.

3.Large-scale Potato Chips Making Machine(200-300 kg/h)

Features: Fully automated, large-scale production, supports 24-hour uninterrupted operation, equipped with automatic refueling and filtration systems, reducing unit production costs. Suitable for large food enterprises and chain snack brands.

Equipment configuration: Hopper → Drum washing → Potato sorting machine → Water bucket elevator → Screw washing and peeling machine → High-efficiency slicing machine → Continuous blanching and cooling → Continuous frying machine → Deoiling→ Seasoning → Automatic weighing and packing machine.

Production conditions: The factory needs 1000-1500 square meters of space, divided into raw material, processing, frying, packing, and finished product storage areas to ensure clear material flow and compliance with food safety requirements; a stable industrial power supply, sufficient water supply, and drainage system are required; the frying area needs a fume extraction and ventilation system; the floor must be hardened, non-slip, and waterproof . Each batch consumes 2500-5500L of water and 800-1300kW of electricity. Investment costs are approximately US$200,000-400,000.

Potato Chips Machine Manufacturer's Service and Guarantee

Equipment procurement is only the first step in production; comprehensive after-sales service directly impacts the stability of the production line and the efficiency of business operations. Baixin Machinery provides full-cycle services, including installation, transportation, and warranty.

Installation and technical training

A professional team is responsible for on-site installation and commissioning, and provides systematic training to operators to ensure the smooth start-up and efficient operation of the production line.

|

Install Details |

|

|

1 |

Our company attaches great importance to installation. We have our own installation team. The number of installation personnel has grown from the initial 3 to a current team of 10, and we are still training more people. |

|

2 |

The majority of our equipment upgrades come from the installation site. This is the core aspect through which we ensure the equipment is up-to-date and employs the latest processing techniques. |

|

3 |

Our installation team has installation experience in over 20 countries. Our company encourages business personnel to participate in the on-site installation together with the installation team, providing more professional and high-quality after-sales service. |

|

4 |

After each installation site is completed, our after-sales department, technical department, production department and business department will organize special seminars to ensure that our after-sales service capabilities and equipment quality keep improving. |

|

5 |

After the equipment is delivered, we will provide a list of installation tools that need to be prepared on-site, a material list, and other necessary preparations. |

|

6 |

During the on-site installation process, we will provide training services, including operation of the production line and daily maintenance. |

Transportation Guarantee:

Withyears of export experience, we provide a fully controllable transportation solution to ensure the safe arrival of equipment at the factory.

|

Delivery Steps |

|

|

1 |

The production department, the after-sales department and the business department will check the delivery list one by one to ensure that no details are missed. |

|

2 |

Equipment container planning, providing the most optimal container arrangement plan to ensure the safety of equipment loading, with the minimum number of containers required. |

|

3 |

Establish an order delivery group, and assign a specific person for each batch of goods. Conduct a re-count of the equipment. |

|

4 |

During the shipping process, photos of each device and component are taken for record-keeping. |

|

5 |

After the goods are dispatched, provide the customers with detailed and accurate packing information to make the receiving process as smooth as possible for them. |

|

6 |

During the shipping process, photos of each device and component are taken for record-keeping. |

After-sales service

We offer a one-year warranty, 24/7 online support throughout the production process, and free repair or replacement within 7 days if equipment malfunctions due to quality issues, minimizing the risk of production interruptions.

|

Warranty |

|

|

12 months |

Seller warrants that the Equipment supplied shall be new and shall be free from defects in materials and workmanship for period of 12 months from the date of commissioning and handover of the complete working plant by Seller to Buyer the "Warranty Period"). |

|

7days |

Seller's warranty covers the following:Defects in materials and workmanship of the Equipment.Any defective parts (due to defects in materials and workmanship during the warranty shall be repaired /replaced free of cost within 7days free of cost. |

|

24h |

During the operation of the production line, if any problems arise, we offer 24-hour online prompt responses. |

With the continued growth in potato chips consumption, potato chips making machinery has become a popular investment. Baixin Machinery not only provides large, medium, and small standardized equipment, but also offers customized production solutions based on customer capacity, budget, and factory conditions. If you are planning to enter the potato chips processing industry or wish to upgrade your existing production line, please feel free to contact Baixin Machinery. We will assign you a dedicated project consultant to develop a complete solution based on your capacity targets, investment budget, and factory conditions, providing detailed equipment configuration suggestions, quotation plans, and return on investment assessments to help your project be implemented quickly .

-

200kg/h Potato Chips Production LineSee More >

200kg/h Potato Chips Production LineSee More > -

50kg/h Potato Chips Production LineSee More >

50kg/h Potato Chips Production LineSee More > -

Automatic Stirring Batch Potato Chips Fryer MachineSee More >

Automatic Stirring Batch Potato Chips Fryer MachineSee More > -

Full Automatic Potato Chips Production LineSee More >

Full Automatic Potato Chips Production LineSee More > -

Potato Chips Washing MachineSee More >

Potato Chips Washing MachineSee More > -

Semi-Automatic Banana Chips Production LineSee More >

Semi-Automatic Banana Chips Production LineSee More >

1-1.jpg)

2-15.jpg)