Cassava Peeling Machine and Sorting Line Were Successfully Shipped to Colombia

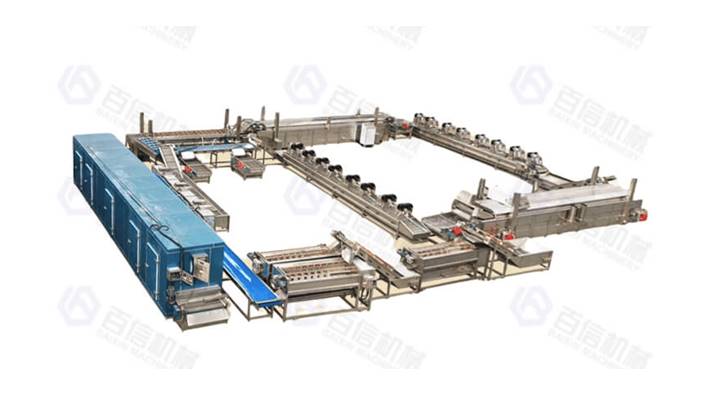

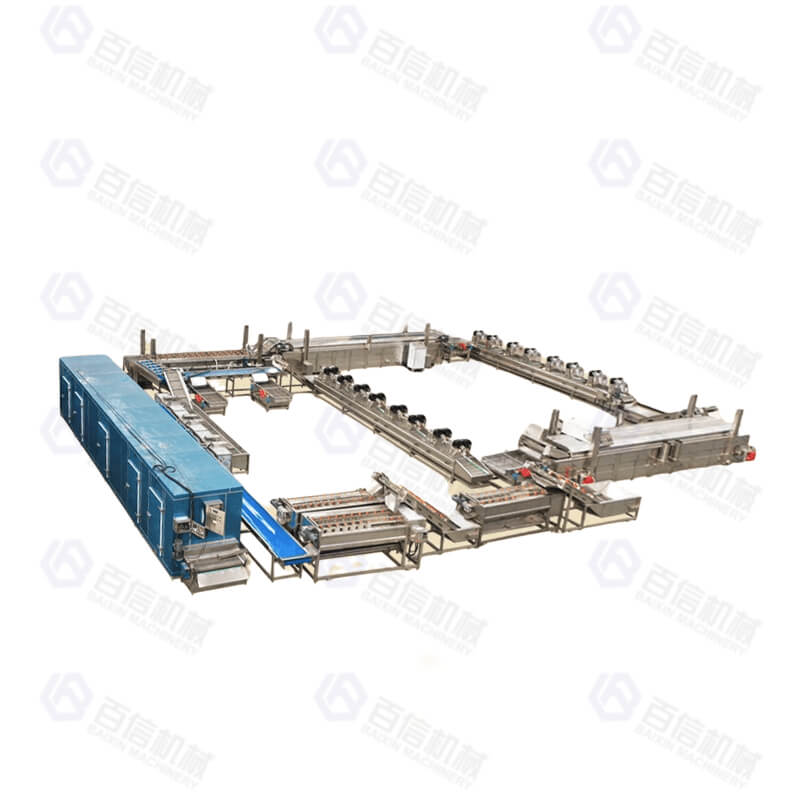

On January 21, 2026 , the cassava peeling machine and matching sorting line customized by Henan Baixin Machinery Equipment Co., Ltd. for a Colombian customer successfully completed production and factory testing, and were officially loaded into a container and shipped to Colombia. This shipment included three cassava peeling machines and one sorting station. The equipment was specifically optimized for the characteristics of local cassava raw materials, boasting advantages such as high peeling rate, low loss, stable operation, and ease of use , effectively improving the customer's cassava primary processing efficiency and product consistency.

Overview of Core Project Information

To help clients quickly understand the overall configuration and execution of this Columbia project , Baixin Machinery has systematically compiled equipment parameters, production cycle, and delivery information. The core information for this project is shown in the table below:

| Exporting countries | Colombia |

| Production line name | Cassava peeling machine + sorting line |

| Manufacturer | Henan Baixin Machinery Equipment Co., Ltd. |

| Heat source | Electricity |

| Electricity consumption | 10KW |

| Water Consumption | 600kg/h |

| Cassava Loss Rate | 5% |

| Cassava Peeling Rate | 98% |

| Cost | $20,000 |

| Production Cycle | 20 Days |

| Container quantity | 1×40HC |

Cassava Peeling Machine Configuration and Processing Technology

Cassava has a thick skin, so to ensure effective peeling, control raw material loss, and meet the needs of continuous production, the Colombian cassava peeling machine is equipped with a specialized spiral roller peeling machine . Through the combined action of mechanical friction and water washing, the cassava skin is efficiently removed. The following will provide a detailed introduction to the structure and working principle of this cassava peeling machine .

In addition, the Colombian customer also equipped the cassava peeling machine with a sorting table, allowing workers to manually peel and sort incompletely peeled cassava during the conveying process , further improving the overall product consistency and providing a good raw material foundation for subsequent deep processing .

In addition, the Colombian customer also equipped the cassava peeling machine with a sorting table, allowing workers to manually peel and sort incompletely peeled cassava during the conveying process , further improving the overall product consistency and providing a good raw material foundation for subsequent deep processing .

Shipping and Packing

This shipment of the Colombian cassava peeling machine and sorting table requires one 40-foot high cube container (40HC).

The equipment is packaged in a moisture-proof and shock-proof manner . Key components are reinforced and secured to ensure safe transport during sea freight . Before leaving the factory, Baixin Machinery has completed a trial run of the entire machine to ensure that it can be quickly installed and put into use after arriving at the customer's factory.

IV.After-Sales Service of Henan Baixin Machinery Equipment Co., Ltd.

As a professional manufacturer of food processing equipment, Henan Baixin Machinery Equipment Co., Ltd. not only prioritizes equipment quality but also focuses on the long-term user experience of its customers. The company has established a comprehensive after-sales service system to provide continuous assurance for the stable operation of its equipment and the safety of its customers' production.

Installation :For Colombian cassava peeling and sorting line projects, Baixin Machinery provides remote technical guidance for installation and commissioning . The equipment undergoes full-machine testing before leaving the factory and comes with detailed user manuals and maintenance information. During installation and trial operation, technicians can guide customers through equipment commissioning via online communication, ensuring the equipment is put into use quickly and stably.

Operation Training: During the equipment delivery and commissioning phase, Baixin Machinery will provide targeted training for customer operators, covering equipment operation procedures, daily maintenance points, and safe usage guidelines. This will help customers quickly master equipment performance, reduce human error risks, and ensure production continuity.

Warranty : During the warranty period, in the event of any malfunction caused by manufacturing or design flaws, Baixin Machinery will provide timely repair or replacement services to ensure the smooth operation of the customer's production schedule.

We thank our Colombian customer for their trust and wish them a successful installation and commissioning. In the future, Baixin Machinery will continue to focus on the food processing equipment field, constantly optimizing product performance and service systems to provide global customers with more efficient, stable, and reliable processing solutions. If you also have needs for cleaning and peeling cassava , potatoes, sweet potatoes, etc. , please feel free to contact Baixin Machinery . We will tailor a professional solution for you.