Potato Chips Machine Price in Ethiopia

In recent years, with the development of the food processing industry and the rising consumer demand for snack foods, potato chip processing has become one of the most popular investment projects among Ethiopian investors. When starting a potato chip processing business, the price of the machinery is often the most important factor for investors. However, the price of potato chip machines is not fixed; the cost ranges from tens of thousands to hundreds of thousands of dollars..This large price difference is due to many factors. This article will analyze the Potato chips machine price Ethiopia from the perspectives of machine composition, process flow, price ranges for different output capacities, and factors influencing price, for investors' reference.

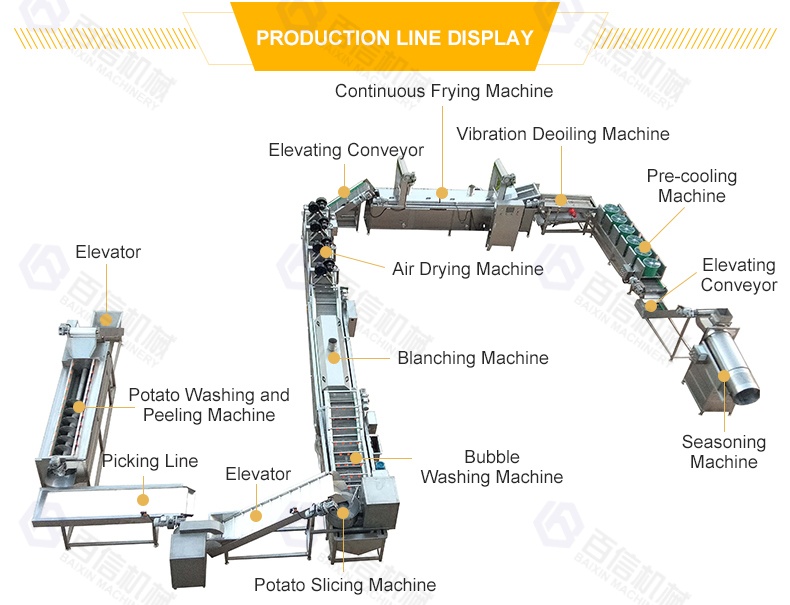

Potato Chip Machine and Technology Flow

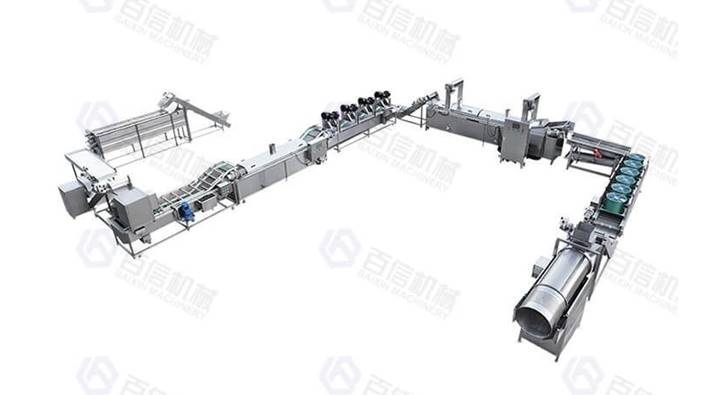

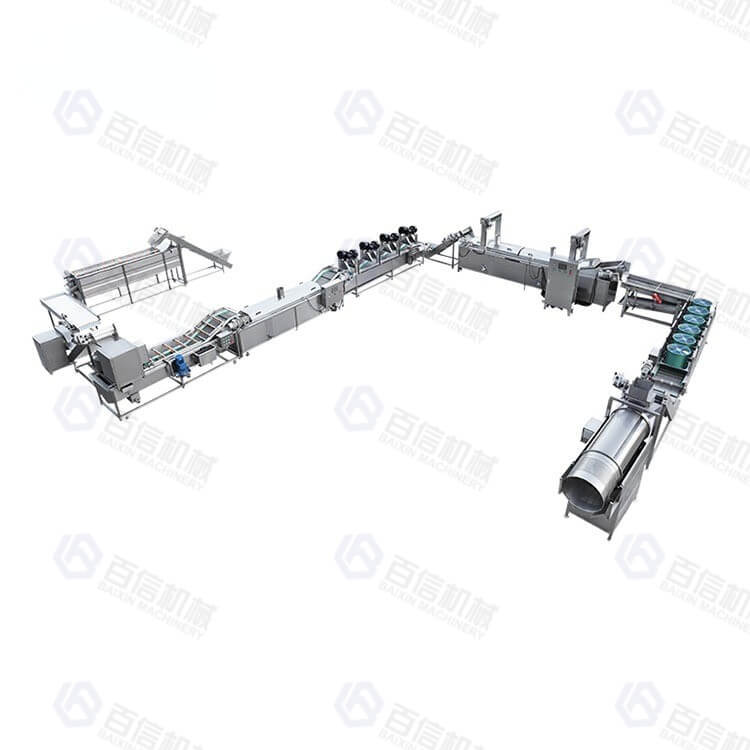

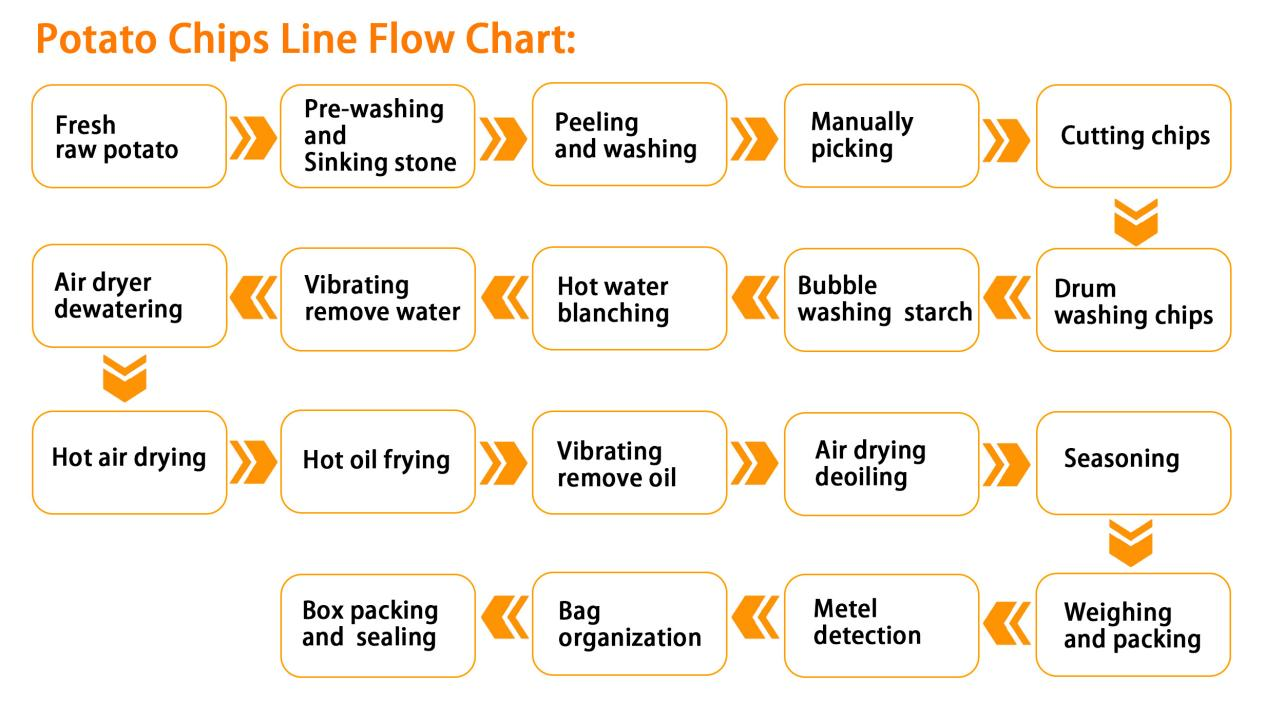

The above machines must be combined to complete the entire processing of potato chips from raw materials to finished product. Based on this, the currently common potato chip production process in the industry is as follows: Fresh potatoes—pre-washing and stone removal—peeling and washing—manual sorting—slicing—drum washing—bubble washing of starch—hot water blanching—vibration dehydration—air drying—hot air drying—hot frying—vibration oil removal—air drying oil removal—seasoning—weighing and packaging—metal detection—bagging—boxing and sealing.

Potato Chips Machine Price in Ethiopia

Because potato chip production lines vary significantly in core configuration, number of equipment, and level of automation, their overall investment costs fluctuate considerably depending on the processing capacity. To help processors of different sizes make precise selections based on their needs, Baixin will provide a detailed analysis of Ethiopian potato chip machine prices and suitable market positioning for small, medium, and large processing capacities, helping investors make informed choices based on their capacity and budget.

1.Small-scale processing capacity (50kg/h)

Core Components: Washing and peeling machine - Slicing machine - Blanching machine - Dehydrator - Manual frying machine- Oil extractor - Seasoning machine - Packaging machine

Project Construction Conditions and Costs: A small-scale potato chip machine occupies approximately 100 square meters and requires 3-5 people to operate. Factory requirements are relatively low; a flat, easy-to-clean floor with good ventilation is sufficient, and basic electricity and water supply are adequate for production. The installation cost of this equipment in Ethiopia is approximately $40,000 to $60,000. Each shift consumes approximately 300-500L of water and 100-150kw of electricity (depending on the heat source).

Market Positioning: Suitable for start-up needs of family workshops and micro-enterprises, with low daily production volumes, especially suitable for investors with small raw material procurement radius and whose main sales channels are local markets or community convenience stores.

2.Medium-sized processing capacity (100kg/h-200kg/h)

Configuration: Water bucket elevator - Spiral washing and peeling machine - Sorting table - Slicing - Water bucket elevator - Blanching machine - Vibrating dewatering machine - Hot air dryer - Frying Machine - Vibrating deoiling machine - Seasoning machine - Packaging machine

Project Construction Conditions and Costs: While a medium-capacity potato chip production line doesn't require the large area or complex infrastructure of a large-scale line, it still necessitates a flat, hardened ground surface and a stable power supply and wastewater disposal capacity. Simultaneously, installation space, ease of operation, and food safety must be considered to ensure stable and efficient production line operation. The entire production line requires approximately 350-1000 square meters of land, with a machine investment cost of $120,000 to $200,000USD. Water consumption per shift is approximately 1500-3500L, and power consumption is 400-500kw (depending on the selected heat source).

Market Positioning: Suitable for medium-sized food enterprises, meeting the supply needs of regional distributors and chain supermarkets, enabling standardized production and batch delivery.

3.Large-scale processing capacity (300kg/h)

Configuration: A large-scale potato chip production line includes a storage silo, drum washing system, potato sorting machine, water bucket elevator, screw washing and peeling machine, high-efficiency slicing machine, continuous blanching and cooling system, continuous frying machine, and supporting equipment such as an oil add machine, oil filter, oil storage tank, seasoning machine, and automatic weighing and packaging machine.

Project Construction Conditions and Costs: To ensure the efficient operation of a large-scale automated French fries production line, the plant and infrastructure must meet corresponding standards. This type of production line occupies approximately 500–750 square meters, and the space planning must consider functional zoning for equipment layout, raw material storage, and finished product temporary storage.

Regarding infrastructure, the following conditions must be prioritized: a stable power supply to ensure continuous operation of the entire line; a sufficient water supply covering process cleaning, blanching and cooling, and domestic water; and a complete drainage system to meet the timely discharge of production wastewater and environmental protection requirements.

The installation price of this type of production line in Ethiopia is approximately $300,000 to $400,000, with a water consumption of 4000-5500L per shift and a power consumption of 1000-1300kw (depending on the heat source configuration). The required number of operators is 4–6 people.

Market positioning: Serving large food groups or multinational corporations, meeting nationwide distribution and export needs, and achieving standardized, continuous and intelligent production throughout the entire process.

Other Factors Affecting Prices

Production capacity is a key factor influencing the price of potato chips machine in Ethiopia, but it's not the only one. The materials and manufacturing processes, heating methods, and brands of electrical components such as motors also affect the overall cost to some extent.

1.Equipment Materials and Manufacturing Processes: In potato chip machine, materials and manufacturing processes significantly impact overall cost. Taking Baixin Machinery's equipment as an example, their production lines typically use high-quality 304 food-grade stainless steel, 1.5mm-3mm thick, to meet food hygiene and corrosion resistance requirements. Besides materials, Baixin Machinery also strictly controls details such as welding processes, surface polishing levels, and processing precision to ensure machine quality and lifespan.

2.Heating Methods: The fryingand blanching machine are core machines in the potato chip productionline. Different heating methods, such as electric heating and gas heating, result in significant differences in equipment price, energy efficiency, and maintenance costs. Specific costs need to be calculated based on different production volumes.

3.Component Brands: Machines equipped with high-performance brand motors and high-quality electrical components will have higher costs than ordinary ones, but they ensure long-term efficient operation and reduce failure rates and maintenance costs. Baixin Machinery uses internationally renowned brands such as Siemens motors and Chint electrical components, which greatly extends the machine's lifespan.

The Strength of Potato Chips Machine Manufacturers

To ensure the smooth commissioning and operation of a potato chip processing project, investors need to pay attention not only to the price of the processing machines but also to the manufacturer's guarantees in installation, commissioning, logistics, and warranty services. Baixin Machinery provides a systematic after-sales service standard for these key aspects to ensure the smooth implementation and long-term stable operation of the customer's production line.

Installation: For projects requiring installation, Baixin Machinery will arrange an experienced engineering team to carry out the installation work on-site and conduct comprehensive trial runs after installation to ensure smooth production line operation. In addition, engineers will provide training to operators on equipment use and maintenance, helping customers to quickly start production and operate worry-free.

|

Install Details |

|

|

1 |

Our company attaches great importance to installation. We have our own installation team. The number of installation personnel has grown from the initial 3 to a current team of 10, and we are still training more people. |

|

2 |

The majority of our equipment upgrades come from the installation site. This is the core aspect through which we ensure the equipment is up-to-date and employs the latest processing techniques. |

|

3 |

Our installation team has installation experience in over 20 countries. Our company encourages business personnel to participate in the on-site installation together with the installation team, providing more professional and high-quality after-sales service. |

|

4 |

After each installation site is completed, our after-sales department, technical department, production department and business department will organize special seminars to ensure that our after-sales service capabilities and equipment quality keep improving. |

|

5 |

After the equipment is delivered, we will provide a list of installation tools that need to be prepared on-site, a material list, and other necessary preparations. |

|

6 |

During the on-site installation process, we will provide training services, including operation of the production line and daily maintenance. |

Delivery: Baixin Machinery has many years of export experience and has formed a complete and standardized equipment transportation process, which can ensure that each batch of machines is delivered to the customer's site safely, efficiently and accurately.

|

Delivery Steps |

|

|

1 |

The production department, the after-sales department and the business department will check the delivery list one by one to ensure that no details are missed. |

|

2 |

Equipment container planning, providing the most optimal container arrangement plan to ensure the safety of equipment loading, with the minimum number of containers required. |

|

3 |

Establish an order delivery group, and assign a specific person for each batch of goods. Conduct a re-count of the equipment. |

|

4 |

During the shipping process, photos of each device and component are taken for record-keeping. |

|

5 |

After the goods are dispatched, provide the customers with detailed and accurate packing information to make the receiving process as smooth as possible for them. |

|

6 |

During the shipping process, photos of each device and component are taken for record-keeping. |

Warranty:We offer a one-year warranty on all equipment and maintain a 24/7 online response mechanism during production line operation to ensure timely resolution of any issues. For malfunctions caused by defects in the equipment itself or the manufacturing process, Baixin Machinery will provide repair or free replacement services within 7 days of purchase.

|

Warranty |

|

|

12 months |

Seller warrants that the Equipment supplied shall be new and shall be free from defects in materials and workmanship for period of 12 months from the date of commissioning and handover of the complete working plant by Seller to Buyer the "Warranty Period"). |

|

7days |

Seller's warranty covers the following:Defects in materials and workmanship of the Equipment.Any defective parts (due to defects in materials and workmanship during the warranty shall be repaired /replaced free of cost within 7days free of cost. |

|

24h |

During the operation of the production line, if any problems arise, we offer 24-hour online prompt responses. |

In summary, potato chips machine price in Ethiopia fluctuates significantly. Therefore, before investing, companies need to conduct a comprehensive evaluation based on their own production capacity needs, market positioning standards, factory conditions, and equipment quality. Choosing a reliable supplier is crucial. Baixin Machinery, with its high-quality equipment, advanced technology, and comprehensive installation, commissioning, and after-sales service, can provide professional support to potato chip production companies of all sizes. If you are planning to invest in a potato chip processing project, please contact Baixin Machinery. We will assign a professional project manager to provide you with a customized solution.

1-1.jpg)

2-15.jpg)