All-in-one multi-layer mesh belt dryer is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, and hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degree centigrade. And the dry cycle is 1-5 hours.

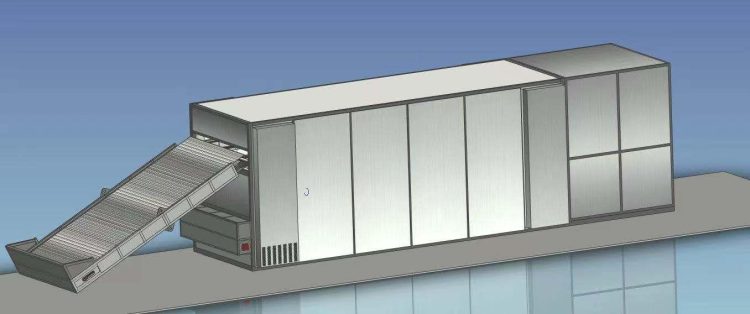

All-in-one multi-layer mesh belt dryer includes a heat source, homogenizer, feed conveyor, output conveyor, observation door, and dryer host.

Advantages of all-in-one multi-layer mesh belt dryer:

1. Middle and low temperature dehumidification drying

The Baixin customized conveyor mesh belt large material dehydrator drying fruits and vegetables in 50℃-80℃, articles do no damage, no moldy and maintain nutrition.

2. Use heat pump technology

The Baixin customized conveyor mesh belt large material dehydrator with high efficiency through the use of a heat pump system for removing air humidity.

3. Working in a wholy sealed drying system, hygiene, and energy conservation

Drying in a close sealed system, no fpreign material popution. Efficiency is irrelevant to the external environment, which can maintain high energy efficiency at all seasons. No hot air and water vapor loss maximize energy recovery.

4. Running Stable, operating easily

A graphical touch control system, automatic intelligent control and demands no human duty after setting.

Application of all-in-one multi-layer mesh belt dryer:

The mesh belt dryer machine is suitable for food series, vegetable series, fruit series, pharmaceutical series, agricultural and sideline products of large-scale continuous dehydration drying. It is an ideal choice for large enterprises to dry fruits, vegetables, flowers, leaves, meat, pet snacks, herbs, spices, nuts, seeds, and seafood.

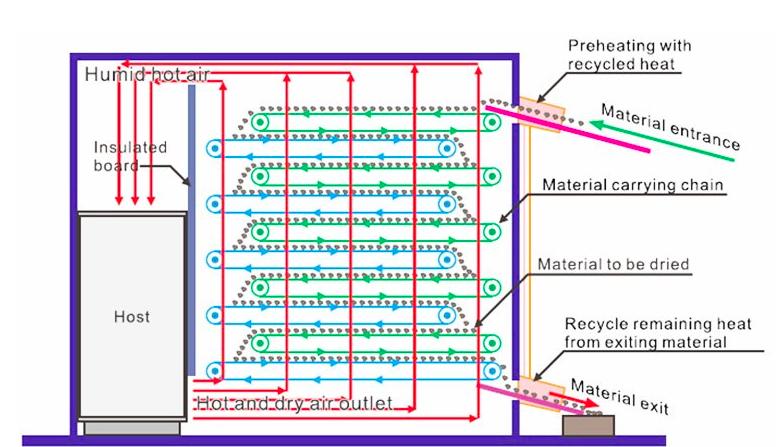

1:Place the material on the conveyor belt of the dryer machine. The material is spread on the feeder by the homogenizing device on the conveyor belt. The stacking thickness of the material is 10-20CM.

2:After the material enters the dryer machine, it runs in an "S" shape in the dryer. The transmission part of the dryer machine adopts a variable-frequency speed-regulating motor, which can control the internal operation time of the drying according to the difference of the water content of the material.

3:The wind speed and wind pressure generated by the hot air blower make the hot air fully and evenly distributed inside the dryer machine. Because the lower pressure is greater than the upper pressure, the hot air naturally moves upward, passing through each layer of the mesh belt, plus the movement and rolling of the material, Make the material fully contact with the hot air, fully heat exchange, and improve the drying efficiency. The dried material will drain through the last layer.

| Continuous mesh belt dryer list | |||||||

| Model | Operation

temperature |

Drying time | Thickness of the material | The size of motor | Capacity | Heat source | Total power |

| BX-2*6M | 40-120℃ | 0.5-5h | 50-200mm | 6*2*2.5 | 200-400kg/h | electricity | 66.5kw |

| natural gas/propane | 12.22kw | ||||||

| coal/wood chips | 13.72kw | ||||||

| steam | 11.22kw | ||||||

| BX-2*9M | 9*2*2.5 | 500-800kg/h | electricity | 79.76kw | |||

| natural gas/propane | 20.12kw | ||||||

| coal/wood chips | 23.12kw | ||||||

| steam | 16.62kw | ||||||

| BX-2*12M | 12*2*2.5 | 1000-1500kg/h | electricity | 153.12kw | |||

| natural gas/propane | 33.12kw | ||||||

| coal/wood chips | 36.12kw | ||||||

| steam | 25.62kw | ||||||

| The continuous drying machine can be equipped according to the user's requirement and the production demands. | |||||||