Baixin has 15 years of experience in customized solutions for cassava processing lines. Since its establishment, Baixin has been committed to providing the best cassava processing solutions to users around the world. We provide one-stop turn-key project and make different solutions for different demands.

1. We are a professional manufacture to produce cassava flour making machines.

2.Process capacity including input capacity and output capacity and Process flow can be customized according to your need.

3.All equipment in the production line is made of 304 stainless steel.

4.Heating method: Electric heating, Gas heating or Electricity heating and gas heating both in one.

5. We can design floor plan of complete line you need depending on your area' s size.

Cassava processing process

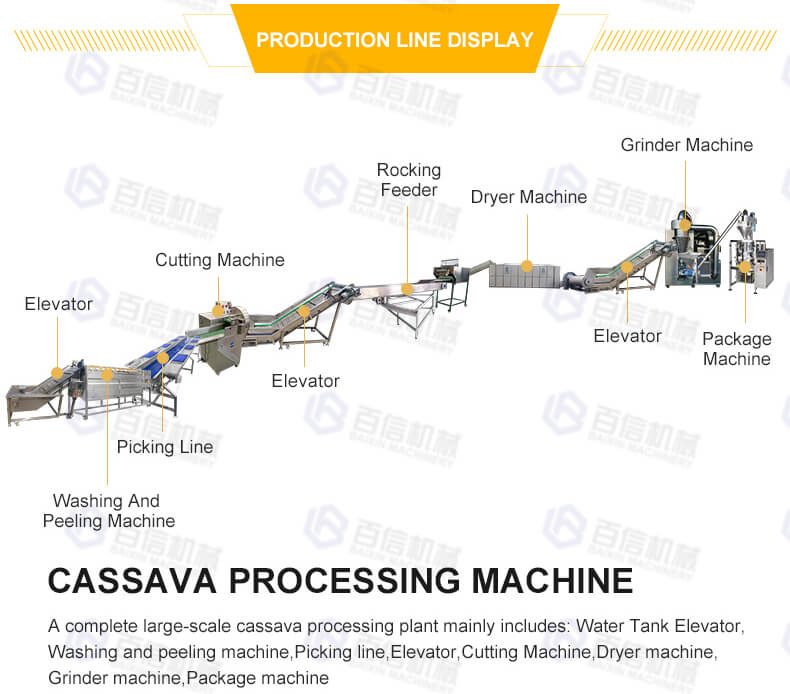

A complete large output cassava flour processing line mainly includes: cassava washing and peeling machine, cassava slicer, cassava chip dryer, cassava grinding machine, packaging machine, etc., each equipment interacts. Connected by a hoist.

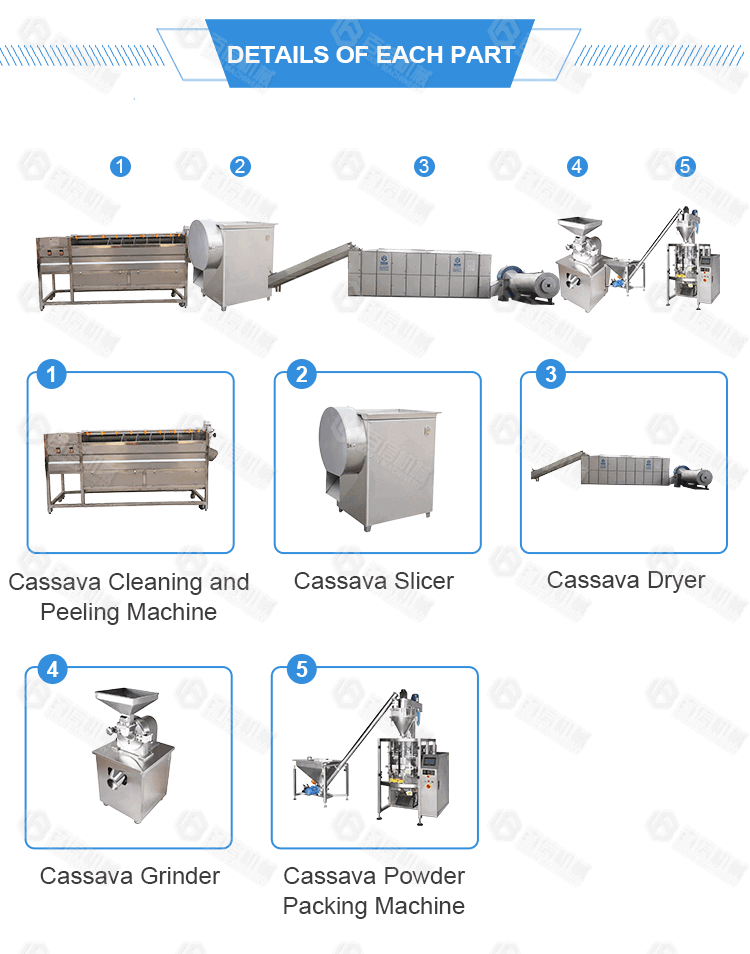

Cassava cleaning and peeling machine: The cassava is placed in the machine, and the brush sweeps and turns the ingredients for cleaning and removing the skin. Then, it enters the spray water section to wash away the dirt that has been brushed on the raw materials until it is washed. The specially designed screw feeding structure is used to realize fully automatic operation.

Cassava slicing machine: Cut the cassava into even slices. The thickness of cassava slices is uniform, and the slice thickness can be adjusted as needed. which has a good effect on the later drying process. This uniform cassava slice can keep the time and effect of the drying process under the same conditions, so the overall drying effect will also be very high, which meets the processing standards of large-scale enterprises in the drying of cassava slices.

Multi-layer belt cassava dryer: The dryer is the key equipment, which determines the effect and quality of cassava after processing. Using our mesh belt type cassava dryer, with an intelligent control system, can make cassava drying is always maintained in a reasonable drying environment to ensure the effect of the finished product. The use of this cassava dryer has the advantages of large processing output, high degree of automation, controllable drying effect and quality, and adjustable drying time. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity, etc.

Cassava powder making machine: Grind dried cassava slices to a fineness of 10-120 mesh. The cassava grinder is air-cooled or water-cooled and can work continuously for a long time.

Cassava powder packaging machine: Generally speaking, cassava powder business requires automatic cassava powder packaging equipment. The cassava powder packaging machine has a PLC control system, which is intelligent and controllable, and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted.