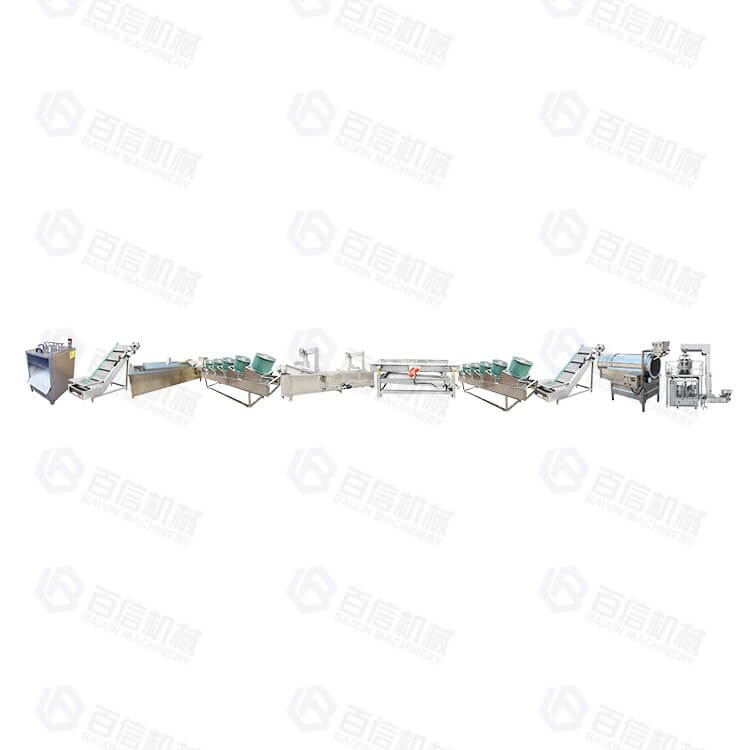

Banana Chip Production Process

Banana chip production is a systematic process from raw material handling to finished product packing, encompassing multiple stages such as banana pretreatment, frying and deoiling, seasoning and packaging, and quality inspection. This article will systematically introduce the complete processing flow, different types of banana chip production machines with varying production capacities, and the comprehensive capabilities of equipment manufacturers in installation, transportation, and after-sales service, providing a reference for companies building banana chip production lines.

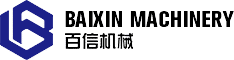

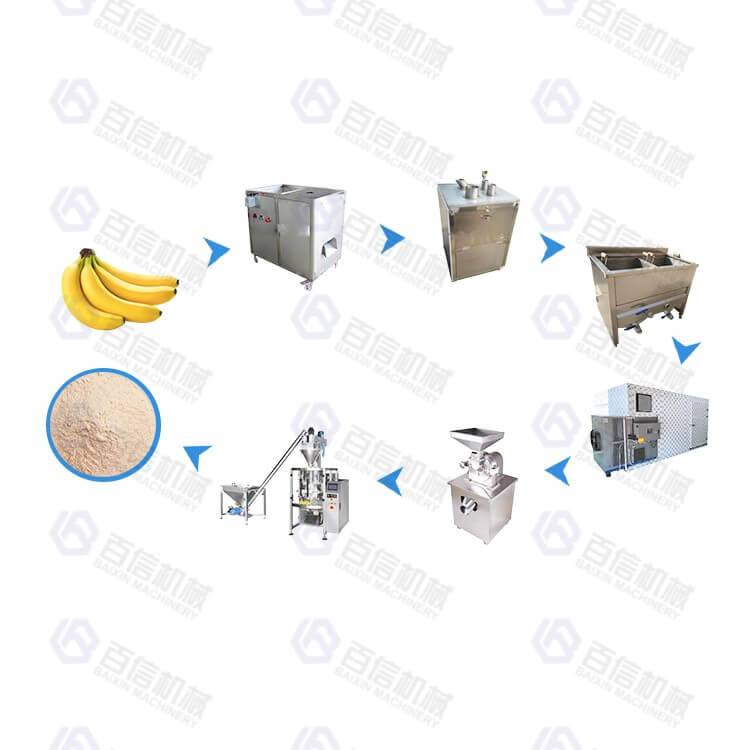

I.Banana Chip Production Process

The production of banana chips is a food processing process that demands high standards of raw material freshness, processing timeliness, and process control. To ensure the color, taste, and food safety of the banana chips, the entire production process requires strictly follow standardized procedures.

Green banana-Hot water blanching and soft the skin-Manually peeling-Cleaning peeled banana-Cutting to chips-Hot oil frying-Vibrating remove oil-Air drying deoiling-Seasoning-Weighing and packing-metal detection-Bag organization-Box packing and sealing

II.Overview of Banana Chip Production Process

1.Raw Material Screening

Not all bananas are suitable for making banana chips. In banana chip production process, unripe green bananas are typically selected . Overripe bananas have too high a sugar content, are prone to caramelizing and turning black during frying , and are difficult to slice . Specific banana selection criteria are as follows:

Shape: Long and narrow, uniform in size, making it easy to slice.

Cooking level: 50%-70% (leaning towards green) is recommended for a crispier result after frying.

Appearance: Smooth surface, free of mold and black spots.

Firmness: Firm, green bananas ensure that the slices remain intact.

2.Hot water blanching

Blanching bananas in hot water can inhibit enzymatic browning, preserve the color of the flesh, and soften the flesh for easier peeling and slicing.

3.Peel manually

Banana peels and residual fibers are removed manually to ensure neat slices, reduce breakage, and improve the quality of subsequent processing .

4.Washing

Use a bubble washing machine to thoroughly clean the banana pulp, removing impurities and residues, ensuring hygienic processing and food safety.

5.Slicing

Slice the bananas into thin slices (1-5 mm), ensuring they are fried evenly.

6.Frying

The sliced banana chips are fed into a continuous fryer at an oil temperature of about 160-180 ℃ . The banana chips are then fried for 3-5 minutes to dehydrate them, turn them golden brown, and create a crispy texture.

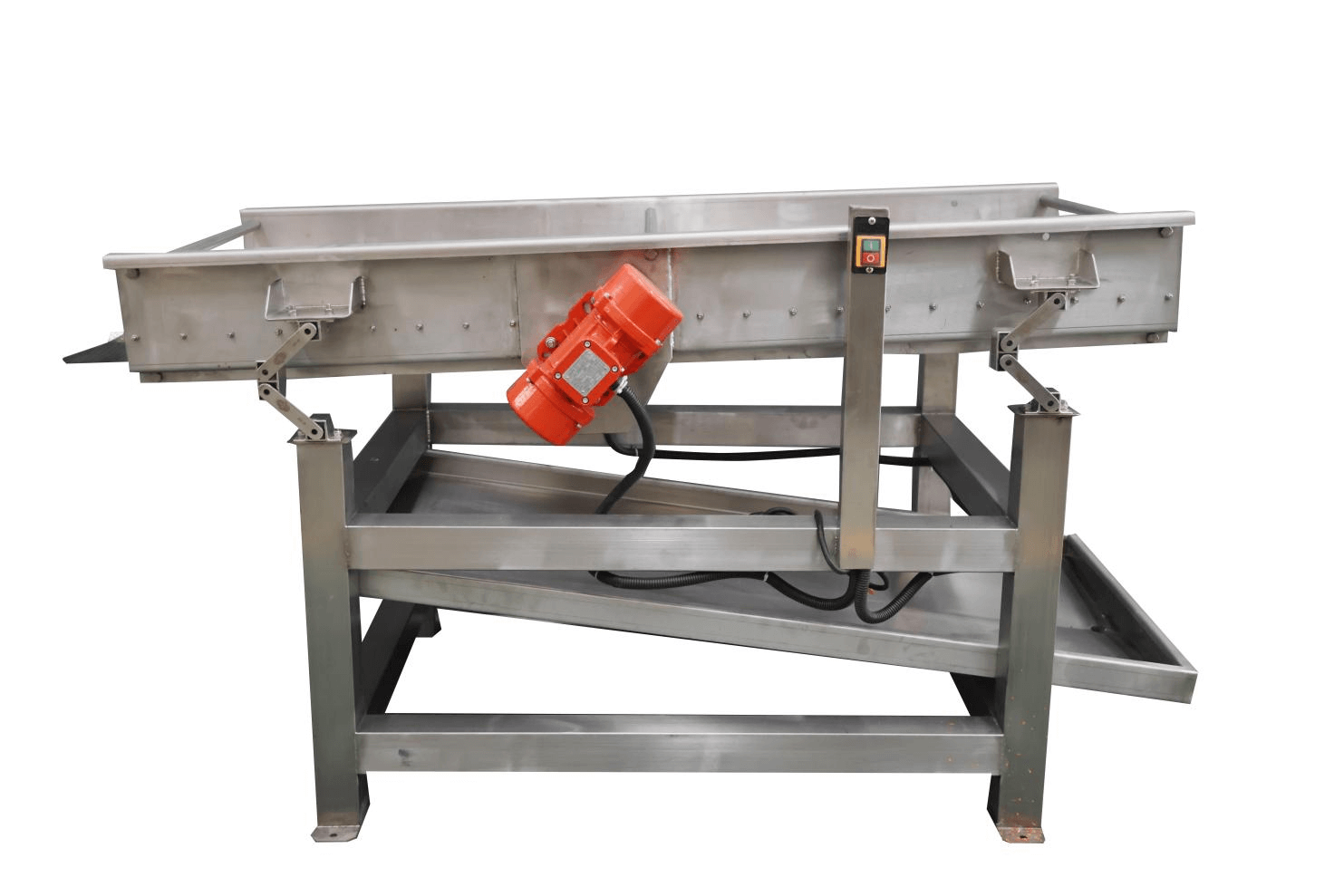

7.Vibration Deoiling

Using a vibratory degreasing machine, the surface oil of banana slices is quickly removed through vibration .

8.Air Drying

High-speed, powerful airflow removes surface oils from banana chips, effectively reducing their oil content.

9.Seasoning

After air-drying, the banana slices are fed into a seasoning machine to be evenly coated with food-grade seasoning .

10.Packing

Package the banana chips according to the preset weight or quantity.

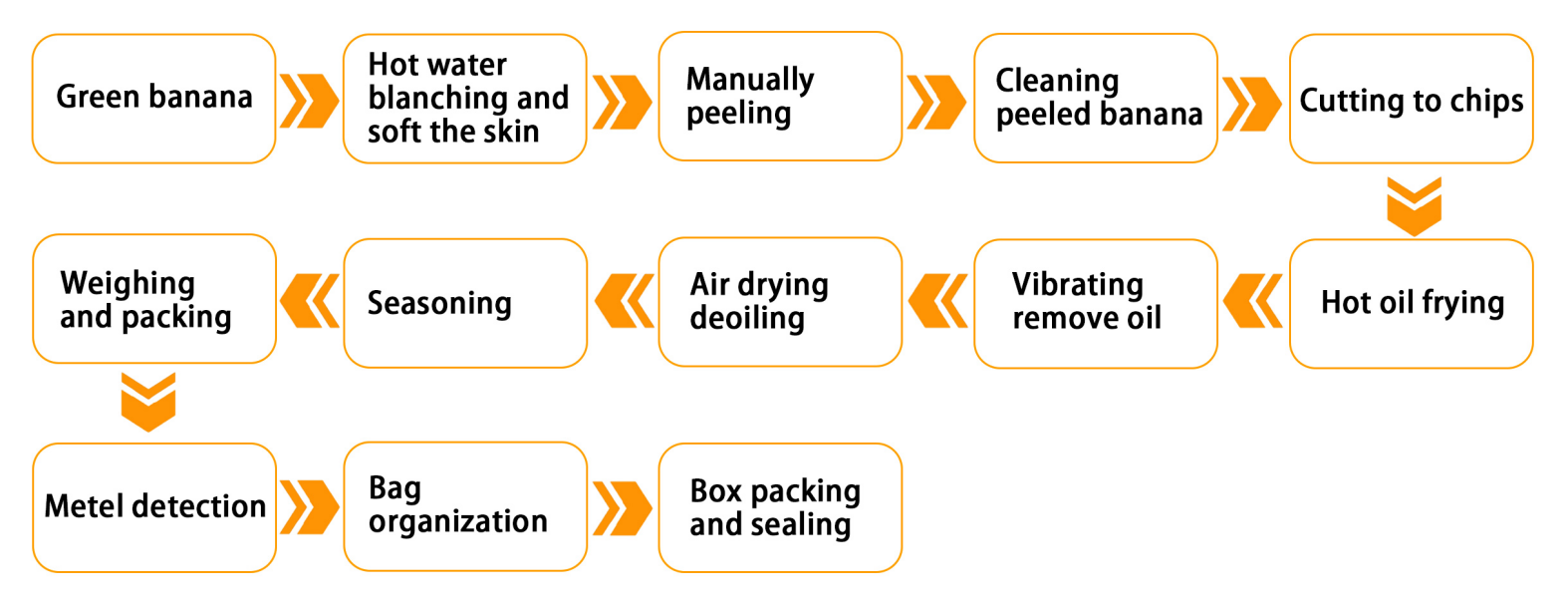

III.Types of Banana Chip Production Machines

Based on production scale and level of automation, banana chips making machine can be divided into three categories, each suited to the production and budget needs of different enterprises:

(1) Small-scale processing capacity (50kg/h)

Advantages: Small banana chip production machines are suitable for initial investors or small-scale processing plants. They have the advantages of low investment, quick start-up, and short payback period, while effectively controlling costs while ensuring basic processing quality.

Project resource requirements:

The entire production line occupies approximately 120 square meters and can be used in a standard factory building. Requirements for water supply, electricity, and drainage are relatively low. Equipment investment is approximately US$50,000–60,000. Water consumption is 300–500 L per shift, and electricity consumption is 60–100 kW (depending on the heat source). 5–6 operators are required.

(2)Medium-sized processing capacity (100kg/h–200kg/h)

Advantages: Medium-sized banana chip production machines strike a good balance between automation, investment costs, and production capacity stability, making them suitable for regional wholesalers, food brand factories, and chain suppliers to expand production and enhance market competitiveness.

Project resource requirements:

The entire line occupies approximately 350–750 square meters and requires a stable water and electricity supply system. Equipment investment is approximately US$90,000–160,000. Each shift consumes 1,500–3,500 liters of water and 200–400 kilowatts of electricity. Normal operation requires only 3–5 people.

(3)Large-scale processing capacity (200kg/h–300kg/h)

Advantages: Large-scale banana chip production lines can operate continuously and around the clock, with a high degree of automation and low reliance on manual labor. A sophisticated oil circulation and automatic oil filtration system ensures stable product quality and reduces long-term oil consumption costs, making it suitable for providing a stable supply to large supermarkets and restaurant chains.

Project resource requirements:

The factory area is approximately 1000㎡, requiring a stable power supply, water supply, drainage, and oil disposal system. Each shift consumes 4000–5500 L of water and 400–500 kW of electricity, requiring 3–4 operators. The total investment is approximately US$200,000.

In addition to the above outputs, Baixin Machinery can also provide customized solutions for banana chip production lines of 500kg/h and 1000kg/h. If you need a larger output, please call us to get a quote for the larger output and energy consumption requirements.

IV.The Strength of Banana Chip Processing Machine Manufacturers

The banana chip processing equipment itself is just the foundation; the installation, transportation, and after-sales service capabilities of the entire production line are also crucial factors that customers must consider before cooperating. A comprehensive service system can significantly shorten the commissioning cycle and ensure the long-term stable operation of the production line.

- Installation and debugging services

Baixin Machinery can dispatch engineers with practical project experience to the site to assist with installation according to customer needs. The engineers will arrange equipment placement, pipeline connections, and overall line commissioning based on the factory layout, and verify that all process parameters meet production requirements through trial runs. Simultaneously, systematic training will be provided to operators, covering equipment use, daily maintenance, and simple troubleshooting, helping customers achieve stable production as quickly as possible.

- Equipment Transportation and Delivery Guarantee

Baixin Machinery boasts extensive export experience and has established a mature and standardized equipment transportation process. We maintain strict control over equipment packaging, protection, and logistics arrangements to ensure that banana chip production equipment arrives at the customer's site safely, intact, and on time.

- Warranty and after-sales support

Baixin Machinery provides a one-year warranty for the complete banana chip production equipment and offers 24-hour online technical support during production line operation. In the event of damage due to equipment quality or manufacturing defects, we will complete repairs or provide free replacement within 7 days, maximizing the continuity and stability of our customers' production.

Banana chip production is a complex system integrating process control, equipment configuration, and service support. From rationally selecting the production scale and matching suitable banana chip processing equipment to relying on support from professional manufacturers with installation, transportation, and after-sales capabilities, these are all key factors for achieving efficient production and continuous stable output. Baixin Machinery has installed banana chip processing plants in multiple countries and regions ,have extensive project experience. For more details about the banana chip production process and machinery, please feel free to contact Baixin Machinery.