Banana Chips Making Machine

Banana chips making machine is a food processing device specifically designed to process fresh bananas into fried banana chips. It is widely used in food processing plants, snack food manufacturers, and small and medium-sized food workshops, and is particularly well-suited to the needs of large-scale, standardized banana chip production. This article will detail the main components, core advantages, and key selection points of this banana chips making machine, helping food processing companies and investors gain a comprehensive understanding of it.

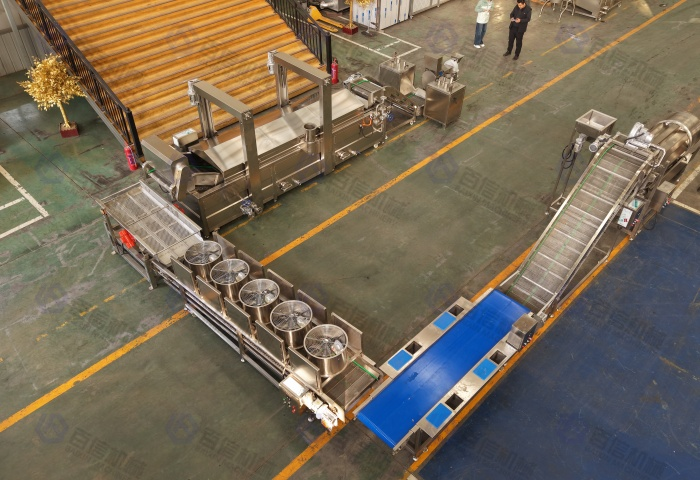

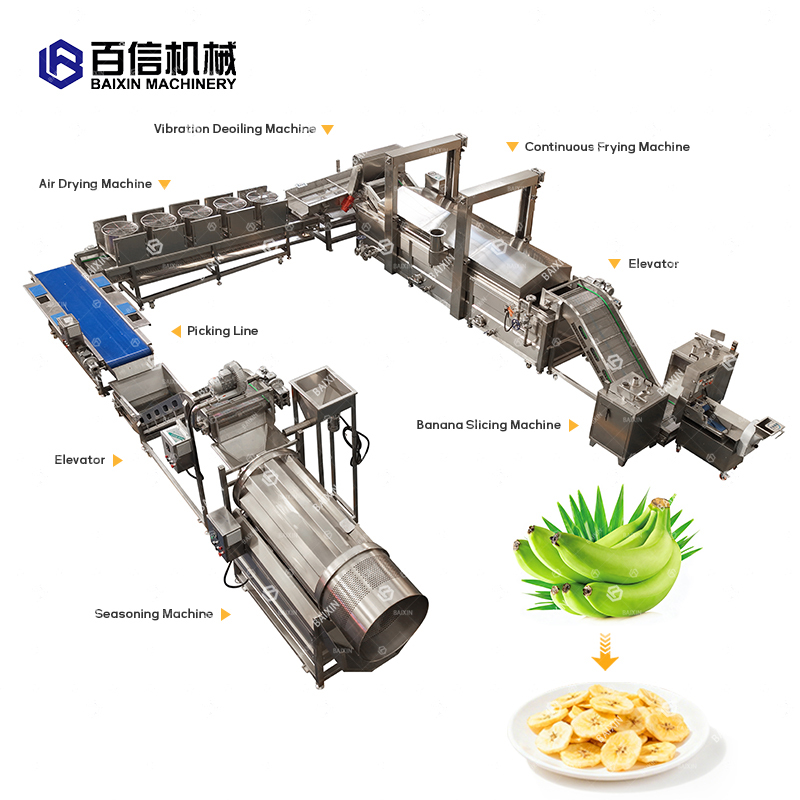

I.Core Equipment and Functions of Banana Chips Making Machine

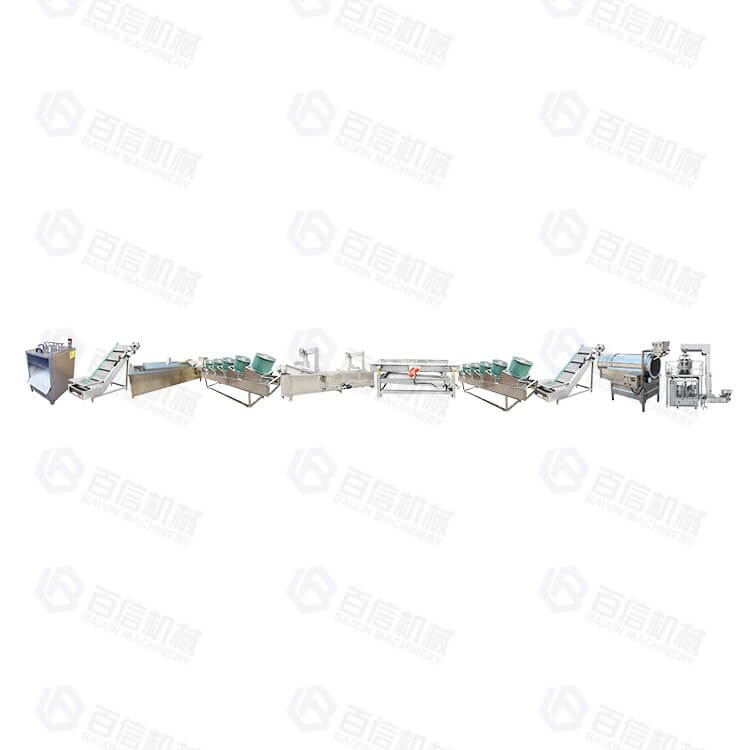

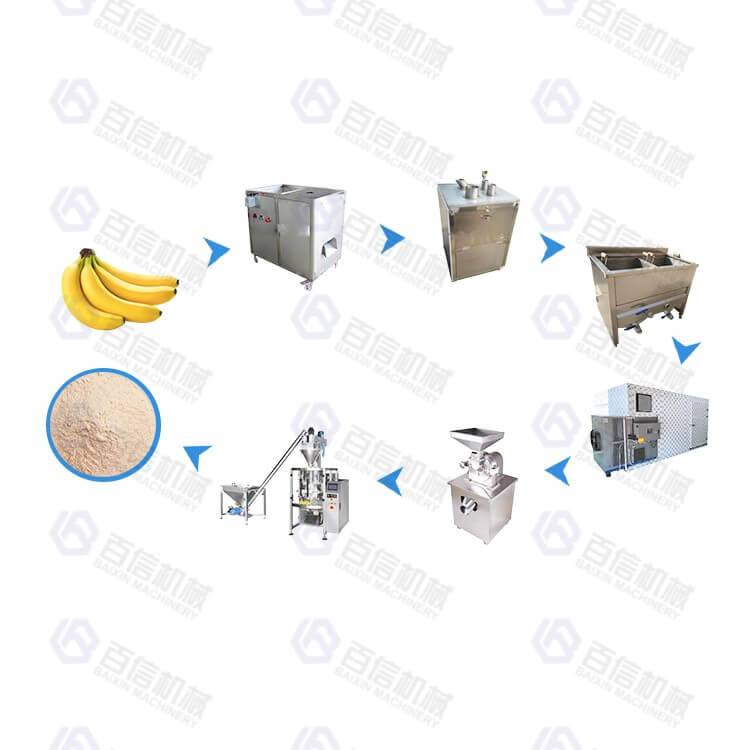

The banana chips making machine is not a single, independent piece of equipment, but a complete production line comprising multiple machines and processes to automate the processing of banana chips. Its core technological flow and corresponding machine functions are as follows:

| No. | Machine Name | Function | Advantage |

| 1 | Banana Slicing Machine | Cutting the banana into slices, sizes adjustable from 1-5mm | 1.Banana chips thickness 1-5mm can be adjustable. 2.Cutting surface is smooth without damage. |

| 2 | Elevating Conveyor | For elevating and conveying the banana slices into next sugar soaking machine | 1.The size can be customized 2.Conveying speed adjustable. |

| 3 | Continuous Frying Machine | For quick frying the banana slices around few minutes in 180°oil | 1.Automatic lifting system, easy to clean. 2.Double mesh belt transmission to avoid the chips floating. 3.Oil filter and recycling system to automatically and continuously filter the oil residue to extend the service life. 4.Electric or gas heating. |

| 4 | Vibration Deoiling Machine | Through high frequency vibrating to achieve deoiling purpose, and also to convey the banana slices uniformly to next machine | The de-oil time is adjustable. |

| 5 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and deoiling the banana slices | 1.The multi-layer mesh belt conveyor belt and special fan outlet completely remove the oil on the surface of the banana slices. 2.Fan can be adjusted up and down. |

| 6 | Elevating Conveyor | For moving banana chips to seasoning machine | 1.The size can be customized 2.Conveying speed adjustable. |

| 7 | Seasoning Machine | Spread the seasoning evenly over each banana chip | 1.With spice tank, the flow of spice adjustable. 2. You can add additives any you want even liquid such as oil, water etc. 3. Seasoning time can be controlled. |

| 8 | Automatic Weighing Packing Machine | For packing the finished banana chips | It can fill Nitrogen automatically, automatic weighing, automatic sealing and automatic packing. |

II.Types of Banana Chips Making Machine

Based on production scale and level of automation, banana chips making machine can be divided into three categories, each suited to the production and budget needs of different enterprises:

(1) Small-scale processing capacity (50kg/h)

Features: This small-scale banana chips making machine is suitable for investors with low production capacity needs who want to start production quickly. It maintains basic processing efficiency while controlling costs, offering advantages such as low investment, quick start-up, and a short payback period.

Configuration: Manual peeler - slicer - manual fryer - deoiling machine - seasoning machine - packing machine

Project Resource Requirements: There are no high requirements in terms of floor space, operational difficulty, or initial investment. The entire line generally requires only 120 square meters of space. Water, electricity, and drainage conditions are also simple; a typical factory building is sufficient. The equipment costs approximately $50,000-60,000, consuming about 300-500 liters of water and 60-100 kw of electricity per shift (depending on the heat source). It requires 5-6 operators.

(2)Medium-sized processing capacity (100kg/h–200kg/h)

Features: Medium-sized banana chips making machines combine high automation, reasonable investment, and stable production capacity, achieving a good balance between efficiency and scale. They are suitable for regional wholesalers, food brand factories, and chain suppliers to expand production and enhance market competitiveness.

Configuration: Raw materials - Manual peeling - Slicing machine - Elevator - Continuous frying machine (equipped with vacuum oil filter and oiler) - Vibrating deoiling machine - Elevator - Seasoning machine - Packing machine

Project Resource Requirements: Medium-sized banana chip production lines have relatively higher requirements for factory conditions. Sufficient space needs to be reserved for equipment layout, logistics flow, and temporary storage of finished products. The floor must have good load-bearing and drainage capabilities, and the power and water supply systems should be stable to support the simultaneous operation of multiple processes such as slicing, frying, and seasoning. The entire line occupies an area of approximately 350–750 square meters, with an investment cost of approximately $90,000–160,000. Each shift consumes approximately 1,500–3,500 liters of water and 200–400 kw of electricity (depending on the heat source configuration). Normal operation requires only 3–5 operators.

(3)Large-scale processing capacity (200kg/h–300kg/h)

Features: Large-scale banana chips production lines can operate continuously around the clock, with production efficiency far exceeding that of small and medium-sized lines. They maintain stable production capacity during long-term operation, significantly reducing reliance on manual labor. Equipped with a complete oil circulation and automatic oil filtration system, they not only extend the oil's lifespan and improve the color and taste of the banana chips, but also effectively reduce long-term oil consumption costs. For enterprises requiring a stable supply to large supermarkets and restaurant chains, large-scale production lines are the most reliable choice.

Configuration: Raw material sorting table - bubble washing machine - blanching machine - water cooler - air dryer - manual peeling - slicing machine - elevator - continuous fryer (equipped with vacuum oil filter and oil refill machine) - vibrating oil remover - air dryer - finished product picking line - seasoning machine - packaging machine

Project Resource Requirements: The planning of a large-scale banana chips production line plant needs to fully consider factors such as equipment layout, logistics routes, raw material and finished product storage areas, and ventilation and oil drainage systems. Furthermore, the production line has high requirements for the stability of electricity and water sources, requiring a sufficient capacity power supply, a reliable water supply system, and efficient drainage and oil drainage facilities to meet the needs of continuous production. The factory needs ample space, typically around 1000 square meters, to accommodate a variety of high-volume banana chip processing machines, including continuous washing, slicing, frying, degreasing, seasoning, and automated packaging. This type of production line consumes approximately 4000-5500 liters of water and 400-500 kw of electricity per shift (depending on the heat source), requires 3-4 operators, and has a total investment cost of approximately $200,000.

In addition to the above outputs, Baixin Machinery can also provide customized solutions for banana chip production lines of 500kg/h and 1000kg/h. If you need a larger output, please call us to get a quote for the larger output and energy consumption requirements.

III.How to Choose Banana Chips Making Machine

Choosing the right banana chips making machine is crucial for ensuring production efficiency and product quality. When purchasing, consider the following key factors:

(1) Define your production needs: Before selecting a banana chip processing machine, you must first clarify your production scale, expected capacity, budget, and factory conditions. The three different types of production lines mentioned above have significantly different processing capacities, investment costs, and factory requirements. Investors should choose based on their own needs to ensure production efficiency and avoid delivery issues due to insufficient capacity or unnecessary investment costs due to oversized equipment.

(2) Focus on machine quality and durability: Equipment quality directly affects production stability and service life. When purchasing, pay attention to the materials of key components (e.g., stainless steel for slicers and fryers to ensure food safety and corrosion resistance), the brand of electrical components (to avoid frequent malfunctions), and the manufacturer's production processes and quality control system.

(3) Assess the manufacturer's strength and after-sales service: In addition to the equipment itself, the overall strength of the equipment manufacturer is equally important. Manufacturers with mature production experience and technical teams can usually provide more stable and reliable banana chips making machines. Meanwhile, a comprehensive after-sales service system, including installation guidance, operation training, and technical support, helps companies quickly resolve problems during equipment use, ensuring production continuity. The following are Baixin Machinery's specific advantages in these areas:

- Baixin Machinery will dispatch professional engineers to the customer's site for installation and commissioning, ensuring stable production line operation, and providing equipment operation and maintenance training.

- Regarding transportation, Baixin Machinery has extensive export experience and standardized transportation procedures, ensuring safe and rapid delivery of equipment to the customer's site.

- Baixin Machinery provides a one-year warranty and 24-hour response during production line operation. During the warranty period, equipment damage caused by material or workmanship defects will be repaired or replaced free of charge within 7 days.

In recent years, the demand for banana chips making machines has been steadily increasing. Whether you are a newcomer to the industry or an existing business planning to upgrade your equipment, a thorough understanding of the working principles, types, and selection guidelines for banana chip making machines is crucial. Baixin Machinery, with years of successful experience, can provide you with comprehensive services from machine selection and customized solutions to transportation and installation. If you need more information about banana chip processing machines, please feel free to contact Baixin Machinery.