Starch Food Dehydrator Delivery To Malaysia

Our Malaysian customers have been in the food processing business. We learned through the internet that we are engaged in the manufacture of drying equipment and consulted with us about starch drying. The customer consulted many drying manufacturers at the same time, and finally chose to make a deal with us, because our equipment is more professional, energy efficient, and highly customized.

The customer requires that the drying output of starch is 1000kg/day, and the heat source is electricity. We recommend the customer to use a heat pump as the heat source, which is more energy efficient.

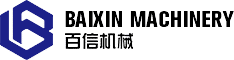

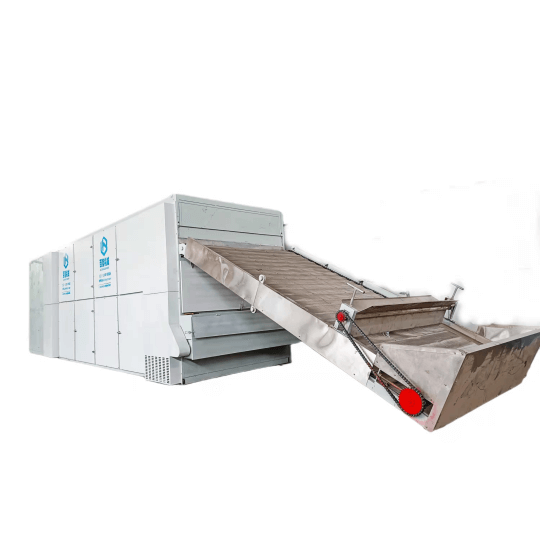

According to the customer's request, we recommended the 8P all-in-one dehydrator to him. The output of this dryer is 1000-1500kg/batch, and the drying temperature is 40-85°C. Installation is simple.

| 8P all-in-one dehydrator | |

| Nation | Malaysia |

| Drying material | Flour Food |

| Capacity | 1000kg-1500kg/batch |

| Dehydration ratio | 75% |

| Drying temperature | 40-85℃ |

| Drying time | 6-24h |

| heat source | electricity |

| Voltage | 380v |

| Power | 8kw |

| Warranty period | 1 Year |

| Core advantages | Small area occupy/ Flexible mobility/ Wide application/ Without installation |

Working principle of all-in-one dehydrator

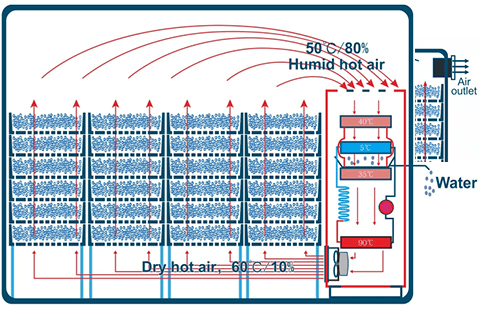

Drying essence is take moisture away, but takes away the moisture temperature is not the most critical factor. The key for drying is depending on relative humidity within certain space, Baixin company took advantage of the dry essence, originality developed a "Closed Cycle" dryer, changed the traditional heat pump dryer "bake" to "dehumidifier”. Its several advantages were unmatched by the traditional heat pump dryer.

Baixin all in one dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation and removable. it is the best drying equipment for small firms, drying experiment and scientific research. The users only connect the power to use, is the easiest operation heat pump dryer.

Flour food dehydrating process

1: Put the flour food on the tray

Spread the flour food evenly on the tray with a thickness of about 5 cm, and then put them in the drying oven.

2: Flour food dehydration

Set the temperature in the drying room to 65°C and the humidity to 10%. Dry for 6~8 hours to complete the flour food dehydration.

3: Storage

The dried flour food will regain moisture when they are in direct contact with the air, so a sealed package is required. If you use vacuum packaging, you can better preserve the color and aroma of flour food.

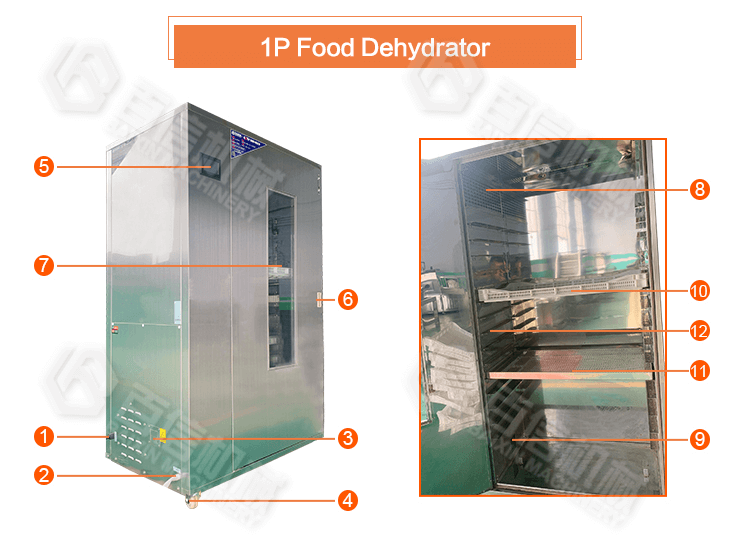

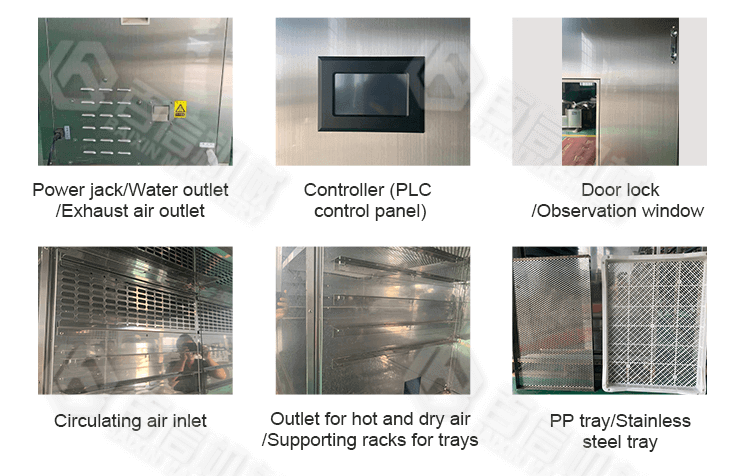

Components of all-in-one dehydrator

Why do customers choose our / All-in-one dehydrator advantages

1:The new dehydration machine All-in-0ne food dehydrator has a compact structure, great energy-saving, wide application, high drying quality, easy operation, simple installation, and movable.

2:It is the best drying equipment for small firms, drying experiments, and scientific research. The uses only connect the power to use, is the easiest operation heat pump food dehydrator.

3:Hot air only circulates inside and no energy is lost. The energy-saving is incomparable to traditional drying machines.

4:Gentle drying at middle and low temperature, Aroma, appearance, and bioactivity are largely retained.

All-in-one dehydrator parameters

| All-in-one dehydrator list | |||||||

| type | machine size(MM) | Capacity (KG) | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 1P | 1180×680×1800 | 50kg-80kg | 1 | - | 15 | - | 600×800 |

| 3P | 2100×930×2100 | 120kg-300kg | 3 | - | 40/60 | - | 600×800 |

| 8P | 4000×1960×2050 | 650kg-1000kg | 8 | 8 | 232 | 600×800 | 600×800 |