French Fries Machine

French fries machine refers to a complete set of processing machinery used for potatoes washing and peeling, cutting, blanching, dehydration, frying, quick-freezing, as well as seasoning and packaging.It enables the automation of the french fries production process, significantly improving efficiency while ensuring consistency in texture and appearance.Baixin Machinery, a professional manufacturer of French fries machines with over ten years of experience, will provide you with a comprehensive analysis of French fries machine and processes, as well as all the necessary knowledge for starting a French fries processing business.

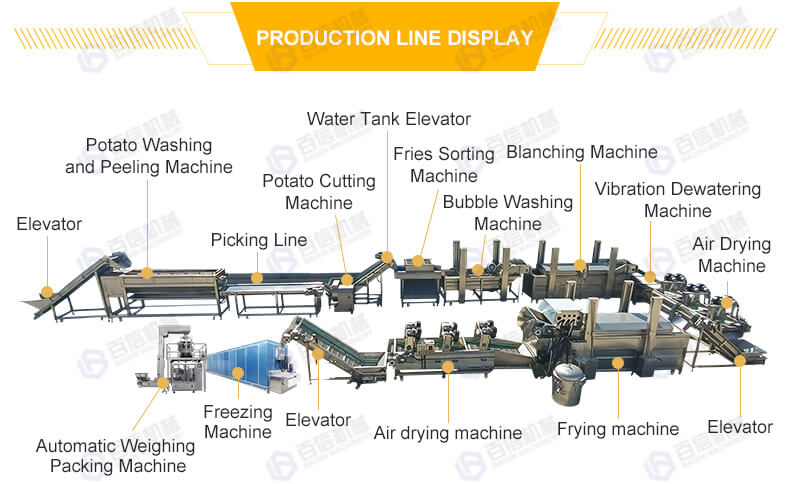

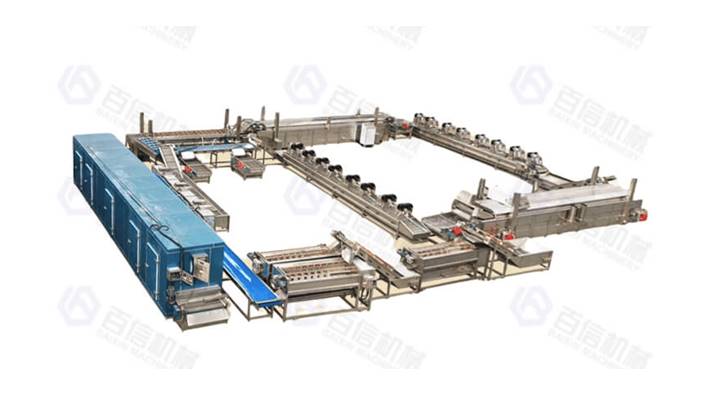

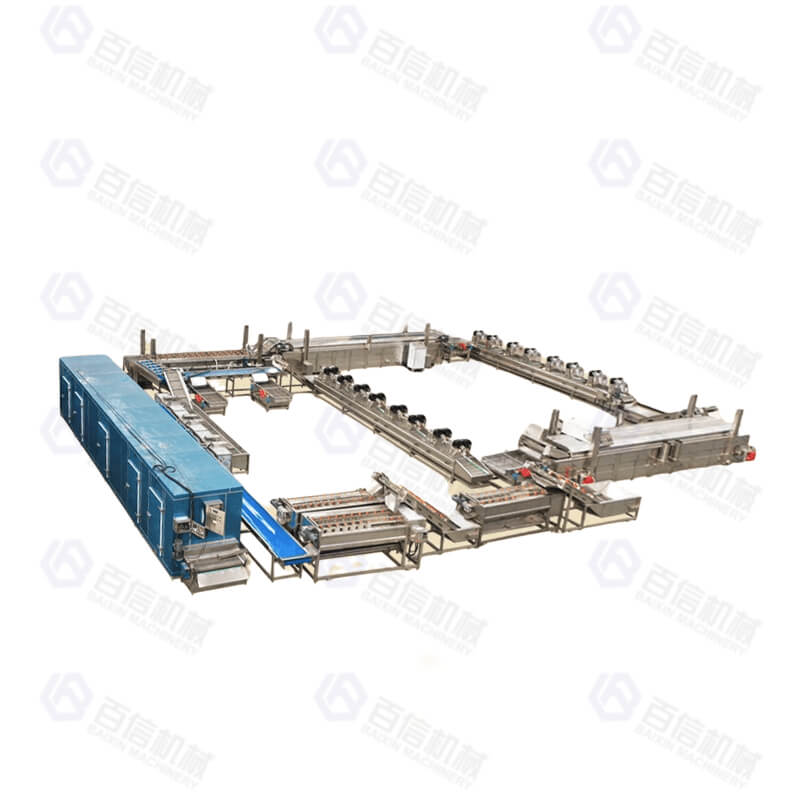

The fully automated French fries machine is shown in the picture below:

| No. | Machine Name | Function | Advantage |

| 1 | Elevating | For elevating and conveying potatoes into the next washing peeling machine | 1.The size can be customized 2.Conveying speed adjustable. |

| 2 | Potato Washing and Peeling Machine | Thoroughly washing and peeling the potatoes | 1. Washing and peeling capacity can be customized. 2. The length of brush can be customized. 3.We use high quality brusher,even old potatoes that are hard to peel can be peeled well. 4.Spraying system to clean the potatoes. 5.Spiral design to make sure automatic discharging. 6. The discharge speed can be adjusted. 7. The whole machine is made of 304 stainless steel. |

| 3 | Picking Line | For manually disposing the uncleaned places and selecting the defective potatoes | 1.Picking table size can be customized 2.Conveying speed adjustable. |

| 4 | Potato Cutting Machine | Cutting the potatoes into fries, sizes adjustable from 7*7 to 12*12mm | 1. The strips' size such as 7*7mm, 8*8mm, 10*10mm and custom made can be changed by adjusting the blade. 2.Cutting surface is smooth without damage. 3.The whole machine is made of 304 stainless steel, High speed stainless steel blades. |

| 5 | Water Tank Elevator | water as buffer to prevent fries breakage, and simply removing starch, meanwhile elevating fries into next step | 1.Conveying speed adjustable. 2.The whole machine is made of 304 stainless steel. |

| 6 | Fries Sorting Machine | Automatically picking up the small pieces fries | 1.Remove the unqualified fries. 2.The screening speed is fast and the quality of French fries is high. |

| 7 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch | 1.Remove the starch from the potato chips. 2.Strong water flow, bubble impact. 3.High pressure spraying system. 4.Filter system and water recycling system. |

| 8 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries | 1.You can use gas, electricity or diesel as power for this machine depending on your needs. 2.It can effectively protect original vivid color of the potato strips/potato chip. 3.You can add additives during blanching process. |

| 9 | Vibration Dewatering Machine | Through vibration to remove the surface water and also to transport the fries uniformly to the next machine | The de-water time is adjustable. |

| 10 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon | 1.The multi-layer mesh belt conveyor belt and special fan outlet completely remove the moisture on the surface of the french fries. 2.Fan can be adjusted up and down. |

| 11 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine | 1.The size can be customized 2.Conveying speed adjustable. |

| 12 | Continuous Frying Machine | For quick frying the fries around 40 seconds in 180°oil to avoid the adhesion and extend the shelf life | 1.Automatic lifting system, easy to clean. 2.Double mesh belt transmission to avoid the chips floating. 3.Oil filter and recycling system to automatically and continuously filter the oil residue to extend the service life. 4.Electric or gas heating. |

| 13 | Vibration Deoiling Machine | Through high frequency vibrating to achieve deoiling purpose, and also to convey the fries uniformly to next machine | The de-oil time is adjustable. |

| 14 | Pre-cooling Machine | Through high pressure wind blowing for pre-cooling and deoiling the fries | 1.The multi-layer mesh belt conveyor belt and special fan outlet completely remove the oil on the surface of the french fries. 2.Fan can be adjusted up and down. |

| 15 | Freezing Machine | Through mechanical vibration and wind pressure, the fluidized quick freezer floats products on stainless steel mesh belt, frozen products and prevent adhesion, achieve IQF | Customized according to customer needs |

| 16 | Automatic Weighing Packing Machine | For packing the finished frozen french fries | It can fill Nitrogen automatically, automatic weighing, automatic sealing and automatic packing. |

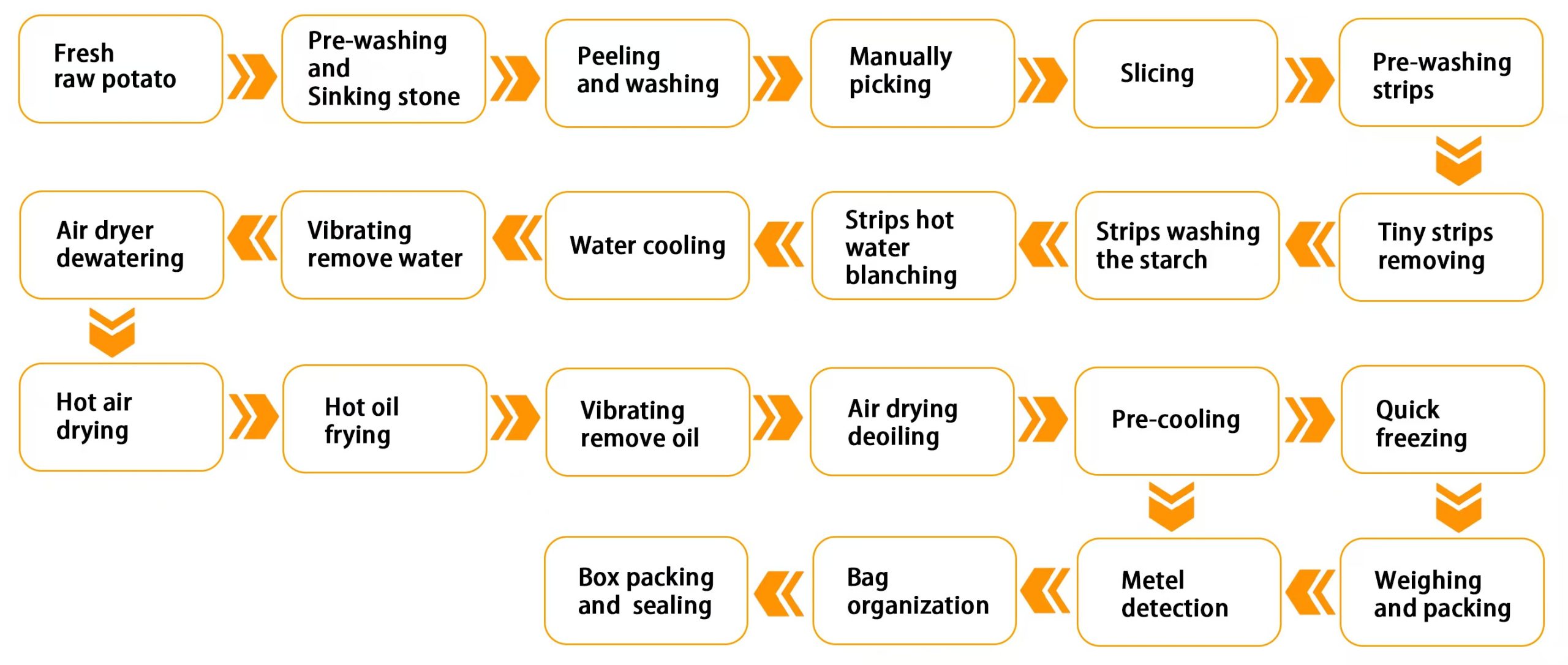

To process potatoes into French fries using these French fries machines, a series of meticulous and orderly steps are required. Currently, the most common processing flow for frozen French fries on the market are as follows:

Fresh raw potato—Pre-washing and sinking stone—Peeling and washing—Manually picking —Slicing—Pre-washing strips—Tiny strips removing—Strips washing the starch—Strips hot water blanching—Water cooling—Vibrating remove water—Air dryer dewatering—Hot air drying—Hot oil frying—Vibrating remove oil—Air drying deoiling—Pre-cooling—Quick freezing—Weighing and packing—Metal detection—Bag organization—Box packing and sealing

Potato Raw Material and Finished French Fries Standards

To ensure consistent quality and excellent taste in processed French fries, and to improve yield and consistency throughout the production process, strict control is required from the selection of potato varieties to the quality standards of the final product. Below are the requirements for suitable potato raw materials for French fries processing and the key quality indicators for finished French fries, which can serve as a reference for production and procurement:

Potato Variety Recommendation:

Shape: The tubers are oblong, large and uniform, with smooth skin and shallow eyes.

Color: Both the skin and flesh are white.

Size: 60-80mm.

The tuber starch content is 15%-17%.The reducing sugar content is less than 0.2%.

Finished Product Standards

Appearance: Uniform pale yellow to golden color, without excessive frost.

Taste: After re-frying or heating, the crust is crispy and the interior is soft and dense.

Moisture content is controlled at ≤65%.

Starch content is 14%-17%.

Reducing sugar content is ≤0.25%.

Guide to Selecting French Fries Machine

The above systematically introduces French fries machine, the complete production process, and the key quality requirements for raw potatoes and finished French fries. However, in actual French fries processing operations, simply understanding the process and product specifications is far from sufficient. To ensure the smooth establishment and long-term stable operation of the production line, the following questions must also be considered: What is the required installation area? What are the factory requirements? What is the energy consumption of the entire french fries production line? How many workers are needed? Based on these questions, as well as the processing capacity requirements for different production scales and the budget differences of investors, Baixin Machinery offers three targeted selection options.

1.Small-scale Processing Capacity (50 kg/h - 100 kg/h)

Features: This small-capacity French fries machine combines manual and semi-automatic processes, offering advantages such as small footprint, low investment cost, and simple operation.

Configuration: Washing and peeling machine → cutting machine →blanching machine→dehydrator → manual frying machine→deoiling machine→seasoning machine→packing machine.

Advantages: This type of French fries machine is the most competitive choice for start-ups or small-scale investors. It has low equipment purchase costs, low financial pressure, and a simple and intuitive process. Employees can learn to operate it after simple training, enabling a quick return on investment.

Project construction conditions and resource requirements: A small-scale French fries machine requires approximately 150 square meters installation area. The factory requirements are relatively low. The ground should be flat and easy to clean, with good ventilation. Basic electricity and water supply are sufficient to meet production needs. This french fries machine price approximately $20,000 to $50,000, consumes about 500L-800L of water per shift, and consumes 20kw -180 kw of electricity (depending on the heat source). It requires 3 to 5 operators.

2.Medium Processing Capacity (200 kg/h - 400 kg/h)

Features: The medium-capacity French fries machine offers a noticeably higher level of automation compared to small-scale equipment, enabling more continuous and stable production.

Configuration: Washing and peeling machine - picking line- cutting machine - water tank hoist - blanching machine - dewater machine - Stirring Batch Frying Machine - deoil machine- quick-freezing machine - packing machine

Advantages: This type of French fries machine has a moderate level of automation, balancing efficiency and cost. It does not require the high investment of large-scale equipment or complex control processes, while significantly improving processing efficiency and reducing reliance on manual labor.

Project construction conditions and resource requirements:Medium-capacity production lines do not require the large area and complex infrastructure of large-scale lines, but they still need to ensure a flat, hardened ground surface, stable power supply, and sewage disposal capabilities. They must also consider equipment installation space, ease of operation, and food safety conditions to ensure stable and efficient operation.

The entire french fries production line requires a floor area of 300 square meters, with an investment cost of approximately $70,000-$200,000. Each shift consumes approximately 1000-1500 liters of water and 50kw-350 kw of electricity (depending on the heat source), requiring 2-4 operators.

3.Large-scale Processing Capacity (500-1000 kg/h)

Features: From raw potatoes to finished French fries, large-capacity processing machines enable fully scaled, automated, and continuous production, making them ideal for large food processing factories.

Configuration: Large-scale systems typically include a raw material Storage silos, fully automatic washing line, screw washing and peeling machine, cutting machine group, continuous blanching and cooling system, continuous frying machine , and supporting equipment such as an oil feeder, oil filter, oil storage tank, IQF freezing tunnel, automatic packing equipment, and Metal Detector—forming a complete French fries production line capable of operating around the clock.

Advantages: Compared with small and medium-capacity systems, large-scale French fries machines offer full-process automation that drastically reduces labor costs. They provide higher energy efficiency, while the oil circulation and filtration systems significantly reduce oil consumption, minimizing the unit production cost for large-volume output. Product quality is stable and highly controllable. For enterprises pursuing high efficiency, high reliability, and compliance with export and industry standards, this equipment is the optimal choice.

Project construction conditions and resource requirements:Large-scale automated French fry production lines place high demands on factory buildings and infrastructure. The factory needs sufficient floor space to accommodate the entire production line, typically requiring 500-750 square meters.

In terms of infrastructure, the production line requires a stable power supply to ensure normal machine operation; a sufficient and stable water source, including process water and domestic water, to meet the needs of washing, blanching, and cooling; and a complete drainage system to ensure timely discharge of wastewater during production, meeting environmental protection requirements. Sufficient space also needs to be reserved for raw material storage and temporary storage of finished products. This type of production line consumes approximately 2500-3500 liters of water and 200kw-1000 kw of electricity per day (depending on the heat source), requires 4-6 operators, and has a total investment cost of approximately $280,000-$450,000.

Of course, in addition to budget and processing capacity, investors also need to consider product positioning, production process, machine materials, supplier strength and after-sales service when purchasing French fries machines, and conduct a comprehensive evaluation.

The Strength of French Fries Machine Manufacturers

Besides equipment selection, after-sales service (installation/transportation/warranty period) of the entire production line is also an important aspect for buyers. Below are Baixin Machinery's after-sales service standards:

Installation: For customers requiring installation coordination, Baixin Machinery will dispatch a professional installation engineer team to the site for installation. After installation, the machine will be tested and debugged to ensure stable operation of the production line. Training on machine operation and maintenance will also be provided to the customer.

|

Install Details |

|

|

1 |

Our company attaches great importance to installation. We have our own installation team. The number of installation personnel has grown from the initial 3 to a current team of 10, and we are still training more people. |

|

2 |

The majority of our equipment upgrades come from the installation site. This is the core aspect through which we ensure the equipment is up-to-date and employs the latest processing techniques. |

|

3 |

Our installation team has installation experience in over 20 countries. Our company encourages business personnel to participate in the on-site installation together with the installation team, providing more professional and high-quality after-sales service. |

|

4 |

After each installation site is completed, our after-sales department, technical department, production department and business department will organize special seminars to ensure that our after-sales service capabilities and equipment quality keep improving. |

|

5 |

After the equipment is delivered, we will provide a list of installation tools that need to be prepared on-site, a material list, and other necessary preparations. |

|

6 |

During the on-site installation process, we will provide training services, including operation of the production line and daily maintenance. |

Delivery: Baixin Machinery has many years of export experience and has a complete and standardized process for machine transportation, ensuring that the machines are delivered to each customer's site quickly, safely and without error.

|

Delivery Steps |

|

|

1 |

The production department, the after-sales department and the business department will check the delivery list one by one to ensure that no details are missed. |

|

2 |

Equipment container planning, providing the most optimal container arrangement plan to ensure the safety of equipment loading, with the minimum number of containers required. |

|

3 |

Establish an order delivery group, and assign a specific person for each batch of goods. Conduct a re-count of the equipment. |

|

4 |

During the shipping process, photos of each device and component are taken for record-keeping. |

|

5 |

After the goods are dispatched, provide the customers with detailed and accurate packing information to make the receiving process as smooth as possible for them. |

|

6 |

During the shipping process, photos of each device and component are taken for record-keeping. |

Warranty: We offer a one-year warranty, and provide 24/7 online support for any issues during production line operation. For machine damage caused by equipment or workmanship defects, Baixin Machinery provides repair or free replacement services within 7 days.

|

Warranty |

|

|

12 months |

Seller warrants that the Equipment supplied shall be new and shall be free from defects in materials and workmanship for period of 12 months from the date of commissioning and handover of the complete working plant by Seller to Buyer the "Warranty Period"). |

|

7days |

Seller's warranty covers the following:Defects in materials and workmanship of the Equipment.Any defective parts (due to defects in materials and workmanship during the warranty shall be repaired /replaced free of cost within 7days free of cost. |

|

24h |

During the operation of the production line, if any problems arise, we offer 24-hour online prompt responses. |

With the rapid development of the fast food and snack food industries, french fries machine have become a necessity in the market. Baixin Machinery not only provides french fries machine of various sizes and capacities, but also offers customized solutions based on different customer needs, budgets, and finished product requirements to meet diverse production needs. If you are interested in french fries machine and the food processing industry, please feel free to contact Baixin Machinery! We will assign a dedicated project manager to create a customized solution for you free of charge, based on your specific needs .