200kg/h Quick Frozen French Fries Production Line Delivery to Bangladesh

Recently, Baixin Machinery Equipment Co., Ltd.'s 200kg/h fully automatic quick-frozen french fries production line, customized for a Bangladeshi client, completed all commissioning work and was successfully loaded and shipped. This production line precisely matches the client's production needs, possessing core advantages such as high efficiency and energy saving, high automation, and stable finished product quality. This shipment not only successfully completed the cooperation between the two parties but will also provide strong support for the large-scale development of the Bangladeshi client'sfrench fries processing industry.

I.Overview of Core Project Information

The key information regarding the 200kg/h quick-frozen french fries production line project in terms of capacity, energy consumption, and delivery is as follows:

| Technical Parameters of 200kg/h Quick-Frozen French Fries Production Line | |

| Exporting Country | Bangladesh |

| Production Line Name | 200kg/h Quick-frozen French Fries Production Line |

| Manufacturer | Henan Baixin Machinery Equipment Co., Ltd. |

| Heat Source | Electricity |

| Electricity Consumption | 311kw |

| Oil Consumption | 10L/H |

| Water Consumption | 500kg/H |

| Workers | 3-4 People |

| Cost | $180,000 |

| Production Cycle | 45Days |

| Number of Containers | 5×40HC |

To ensure the color, texture, and frying stability of frozen French fries, the production line must meet the following raw material and finished product standards.

Potato Raw Material Standards:

Shape: Long oval, large and uniform tubers, smooth skin, shallow eyes.

Color: White skin and flesh.

Size: 60-80mm.

Starch Content: 15%~17%.

Reducing Sugar Content: Less than 0.2%.

Finished Product Requirements:

Appearance: Uniform pale yellow to golden yellow color, with minimal frost on the surface.

Taste: Crispy outer skin and soft, fluffy interior after double-frying or heating.

Moisture Content: ≤65%.

Starch Content: 14%-17%.

Reducing Sugar Content: ≤0.25%.

II.Equipment Configuration and Processing Technology of 200kg/h Quick-Frozen French Fries Production Line

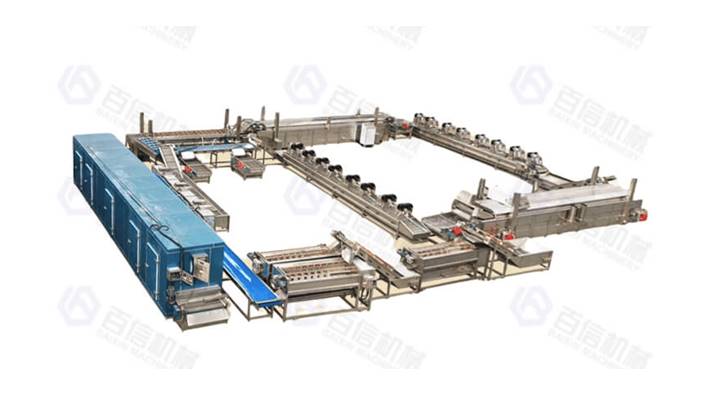

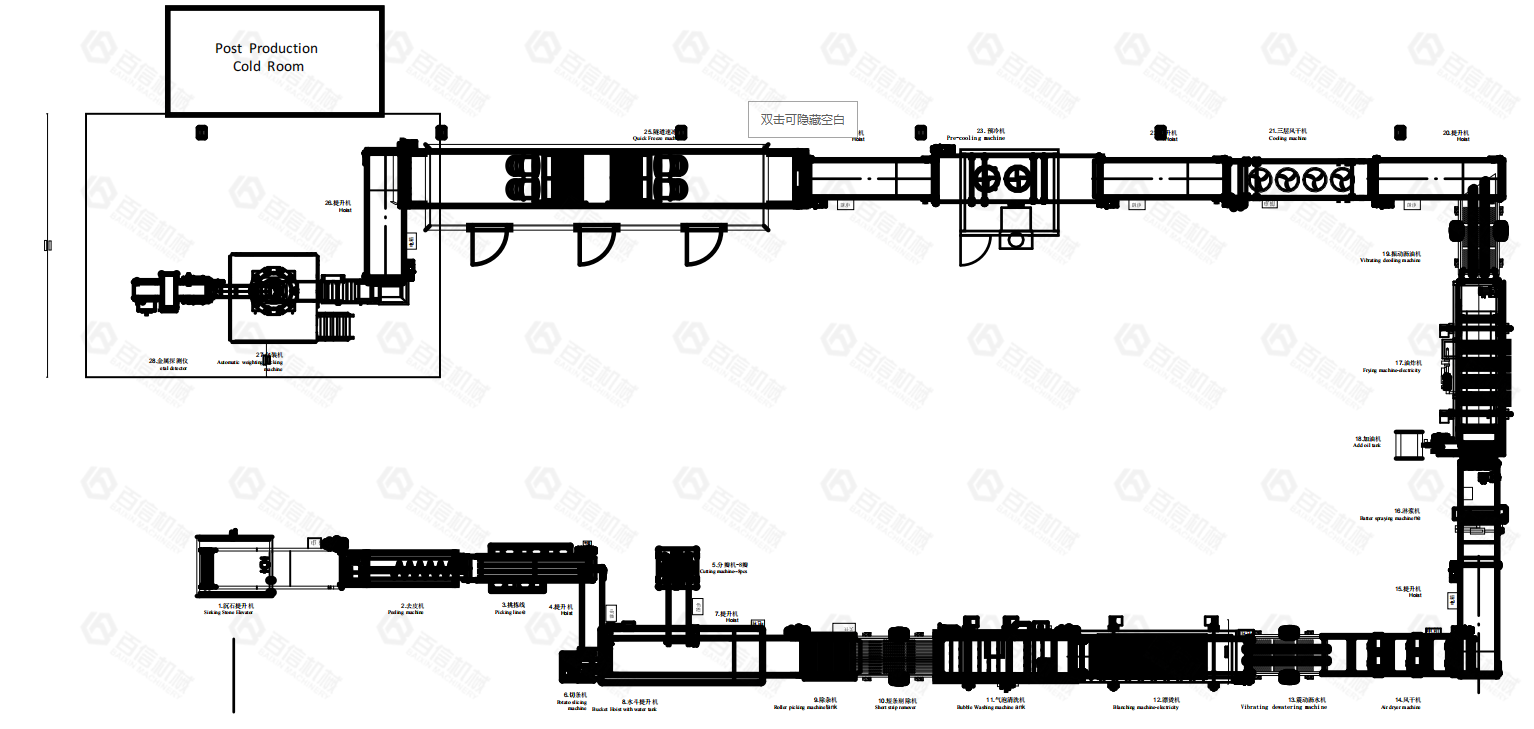

During the project confirmation phase, Baixin Machinery provided a complete equipment layout plan for a 200kg/h quick-frozen french fries production line based on the customer's existing factory size and production needs.

As can be seen from the layout, the entire production line is arranged in a U-shape, with clear material flow and centralized operations, reducing manual handling distances and improving overall production efficiency.

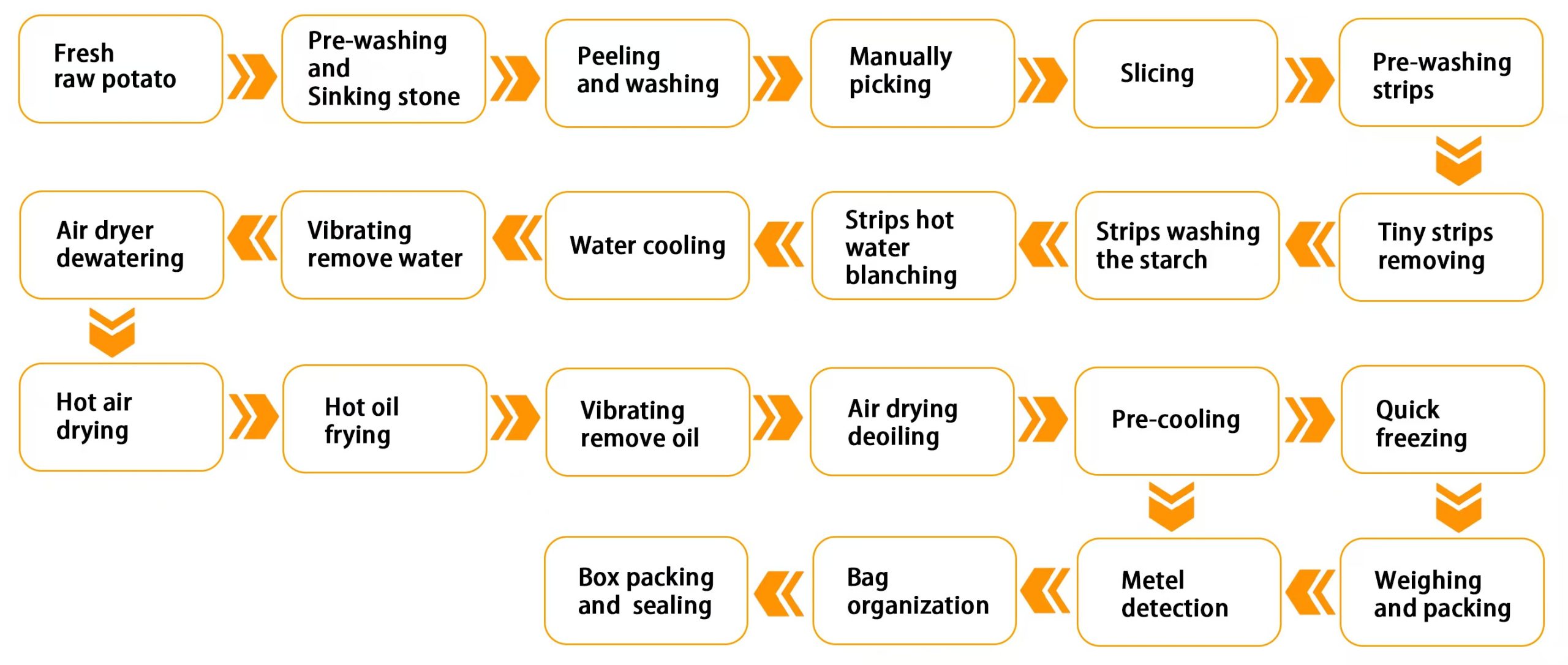

This 200kg/h fully automatic quick-frozen french fries production line uses a continuous process of "washing - peeling - cutting - blanching - dehydration - frying - pre-cooling - quick-freezing - packing" as its core logic. Through the orderly connection of corresponding specialized equipment, it achieves continuous production from potato raw materials to finished quick-frozen French fries, ensuring both production efficiency and stable product quality control.

- The screw peeling and washing machine efficiently removes potato skins while simultaneously washing them with water as the spiral and brush rotate.

- Slicing machine can cut peeled potatoes into sizes of 6*6mm, 8*8mm, 9*9mm, and 10*10mm.

- The water bucket elevator washes and removes surface starch from potatoes, reducing the risk of oxidation and spoilage, and smoothly transports potatoes to the next process.

- The short strip removal machine simultaneously screens and removes substandard short strips; the sieve spacing is 4mm and can be customized, efficiently processing large quantities of fries.

- Bubble washing machine uses bubbles to agitate the fries in the washing tank, deeply removing impurities and starch, and preventing the fries from sticking together.

- Blanching machine uses 60-95℃ high-temperature hot water to deactivate enzymes, preventing subsequent discoloration of the fries, and simultaneously altering the internal structure for a crispier texture.

- The water cooling machine quickly cools the blanched fries, further adjusting the internal structure and optimizing the texture.

- The air dryer machine deeply removes surface moisture from the fries, preparing them for subsequent processes.

- Continuous frying machine quickly fry French fries in cooking oil at 160-180℃ for 30-40 seconds, ensuring a crispy texture and taste;

- Vibration deoiling machine uses vibration to quickly remove surface oil, significantly reducing the oil content of the fries;

- The rapid air dryer further removes residual surface oil;

- An IQF fluidized freezer uses high-speed airflow to suspend the fries in a fluidized state, allowing for rapid freezing through full contact with cold air;

- Automatic weighing and packing machine accurately packages the finished products to preset weights.

Based on the above-mentioned customized configurations for customers, Baixin Machinery has summarized a standardized processing flow for quick-frozenfrench fries production lines for customers with different needs to refer to.

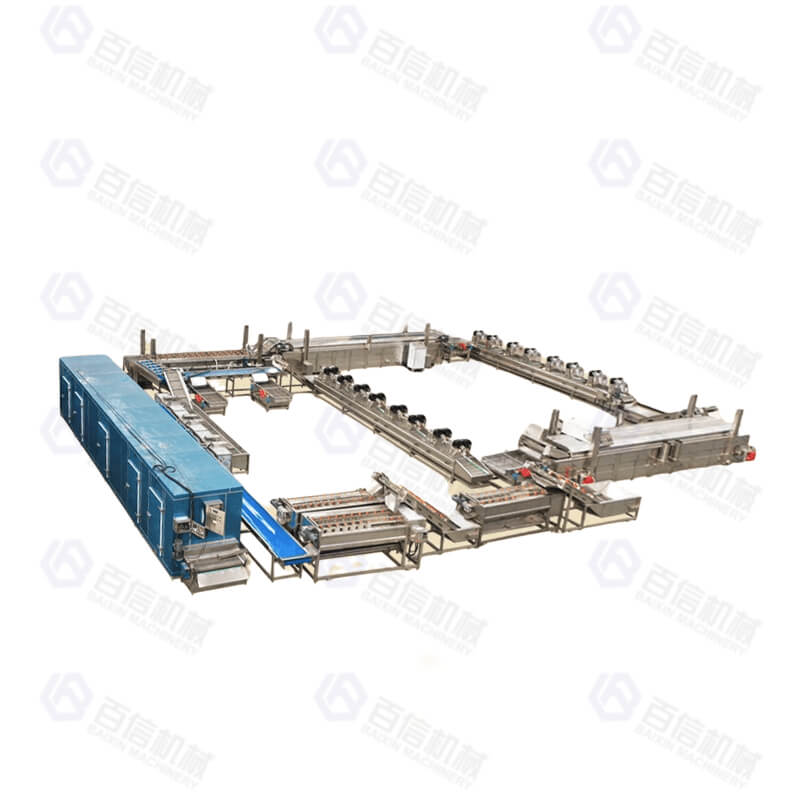

III.Shipping Site

This shipment used five 40-foot high cube containers. All equipment was securely packaged and secured, with adequate moisture and impact protection, and included clear equipment identification and a packing list. Full-line integrated testing was completed before shipment to ensure rapid installation and commissioning upon arrival at the customer's factory. Below are photos of the 200kg/h quick-frozenfrench fries production line being shipped, based on on-site feedback.

IV.After-Sales Service Commitment of Henan Baixin Machinery Equipment Co., Ltd.

Henan Baixin Machinery Equipment Co., Ltd. always adheres to the principle that "product delivery is only the beginning of service." For this Bangladesh project, the company provides the following after-sales support:

Installation : Baixin Machinery will dispatch professional engineers to install and commission the entire production line on-site to ensure the equipment operates normally according to the designed process. Engineers will also provide optimization solutions based on the actual layout of the customer's factory to maximize production efficiency and operational convenience.

Operation Training: Providing comprehensive training to customer operators, including production processes, equipment operation, daily maintenance, and safe operating procedures, helping customers quickly get started and improve production stability.

Maintenance Support: Providing remote technical guidance and on-site service, with 24-hour online response to any problems encountered by customers, ensuring uninterrupted production.

Warranty : The entire production line enjoys a one-year warranty. During this period, for damage caused by equipment or process defects, Baixin Machinery promises to provide repair or free replacement within 7 days.

Henan Baixin Machinery Equipment Co., Ltd. specializes in the research and development and manufacturing of food processing machinery, and its products have been exported to many countries and regions worldwide. The successful shipment of the 200kg/h quick-frozen french fries production line to Bangladesh further demonstrates the company's technical strength and market reputation in the field of automated food equipment. If you are also interested in investing in a French fry production business, please feel free to contact us! We will assign a dedicated project manager to provide you with a customized solution based on your needs, free of charge.