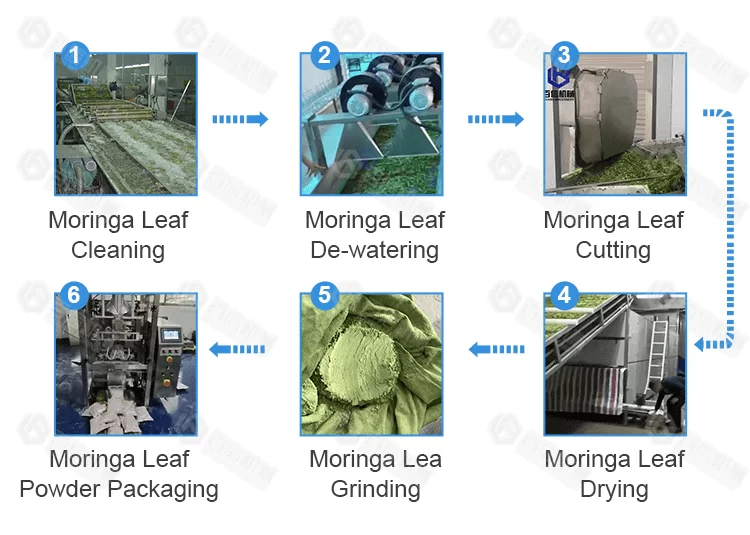

The Moringa leaf powder processing line has continuous automatic production, fast processing speed, high output, and good quality. The picked Moringa leaves are processed into Moringa powder after being cleaned, air-dried, cut into sections, dried, and ground. Moringa leaf powder processing equipment includes moringa leaf washing machine, moringa leaf cutting machine, moringa leaf drying machine, moringa leaf mill, moringa leaf powder packaging machine, and other equipment, which can be used for moringa leaf, moringa leaf powder, and other deep processing. This assembly line equipment is also suitable for processing a variety of fruits and vegetables, such as ginger, garlic, onion, pepper, spices, and so on. The production line adopts advanced technology, the output is high, and the ex-factory price is sold directly. This is the best choice for businesses and the most ideal device.

Moringa leaf washing machine: It is used to clean the dirt, dust and other impurities attached to the surface of Moringa leaves. Moringa leaves are washed and transported under the action of high-pressure water flow and strong air bubbles, and at the same time, appropriate color fixatives and disinfectants can be added to enhance the color of Moringa powder. It is then transported to the next process.

Moringa leaf de-watering machine: Dehydrating Moringa oleifera leaves before drying and air-drying Moringa oleifera leaves can effectively remove water droplets on the surface of Moringa oleifera leaves, greatly shorten the drying time, and improve the subsequent processing efficiency of Moringa oleifera leaves. The Moringa Leaf Air Dryer is specially designed for multiple turning and conveying, fully removing the moisture on the surface of the Moringa Leaf. The equipment adopts frequency conversion conveying, the speed is adjustable, and the conveying is stable.

Moringa leaf cutter: Moringa leaves are cut into sections with uniform length, the speed of the conveyor belt is adjusted by the frequency converter, and the length of the cut sections can be adjusted as required. One machine is multi-purpose, high output, easy to replace the cutter head, easy to operate, and easy to clean.

Multi-layer belt moringa leaf dryer: The dryer is the key equipment, which determines the effect and quality of moringa leaf after processing. Using our mesh belt type moringa leaf dryer, with an intelligent control system, can make moringa leaf The drying is always maintained in a reasonable drying environment to ensure the effect of the finished product. This moringa leaf dryer has the advantages of large processing output, high degree of automation, controllable drying effect and quality, and adjustable drying time. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity, etc.

Moringa Leaf Powder Making Machine: Grind the dried Moringa leaves to a fineness of 10-120 mesh, and obtain the particle size of Moringa powder by selecting screens with different apertures. Moringa leaf grinder has a simple structure, stable operation, low noise, and good crushing effect. Air-cooled or water-cooled, it can work continuously for a long time.

Moringa Leaf Powder Packing Machine: The moringa leaf powder packaging machine adopts a PLC control system, which is intelligent and controllable, and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted. It can automatically complete the tasks of moringa powder measurement and filling, with high precision, small error, intelligent bag delivery, adjustment of bag width, and filling of moringa powder. It is suitable for all kinds of fine powders with good fluidity.

Advantages of moringa leaf powder processing line:

| Large Output Moringa Leaf Powder Processing Line | ||||

| Number | Name | Power | Size | Output |

| 1 | Moringa Leaf Washing Machine | 3.37KW | 3000*1020*1350mm | 1000kg/h |

| 2 | Moringa Leaf Air Dryer | 6KW | 4000*950*1600mm | 1000kg/h |

| 3 | Moringa Leaf Cutter | 1.1KW | 1180*550*1020mm | 500kg/h |

| 4 | Moringa Leaf Dryer | 33.12KW | 12000*2000*2500mm | 1000kg/h |

| 5 | Moringa Leaf Grinder | 5.5KW | 750*600*1260mm | 200kg/h |

| 6 | Moringa Leaf Powder Packaging Machine | 3.5KW | 3000*1500*2600mm | 30-60 packs/min |

| The processing line can be equipped according to the user's requirement and the production demands. | ||||