French Fries Production Line

With the rapid development of the frozen food and fast-moving consumer goods industries, the demand for French fries continues to rise, driving investment in French fries production lines into a period of rapid growth. However, investing in a French fries production line is not as simple as just buying a few pieces of equipment. The real core of the investment lies in understanding the entire production line's technological process, the functional characteristics of key equipment, and the key selection criteria. To help companies reduce trial-and-error costs and improve production efficiency, Baixin Machinery will provide a comprehensive analysis from aspects such as the technological process, introduction to core equipment , and key selection criteria, helping investors make clearer and more accurate judgments when planning French fries processing projects.

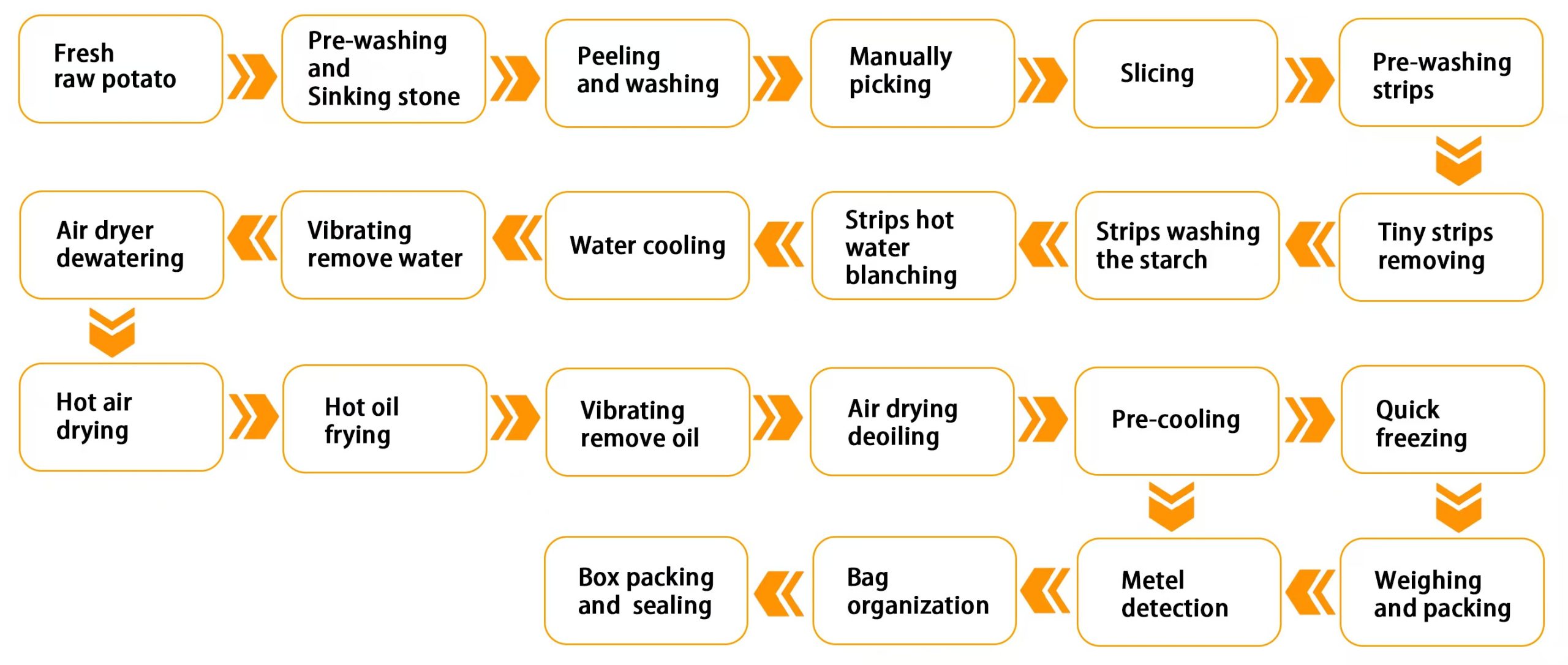

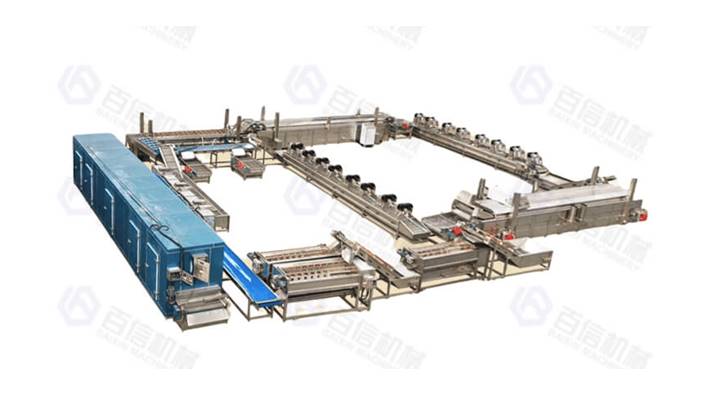

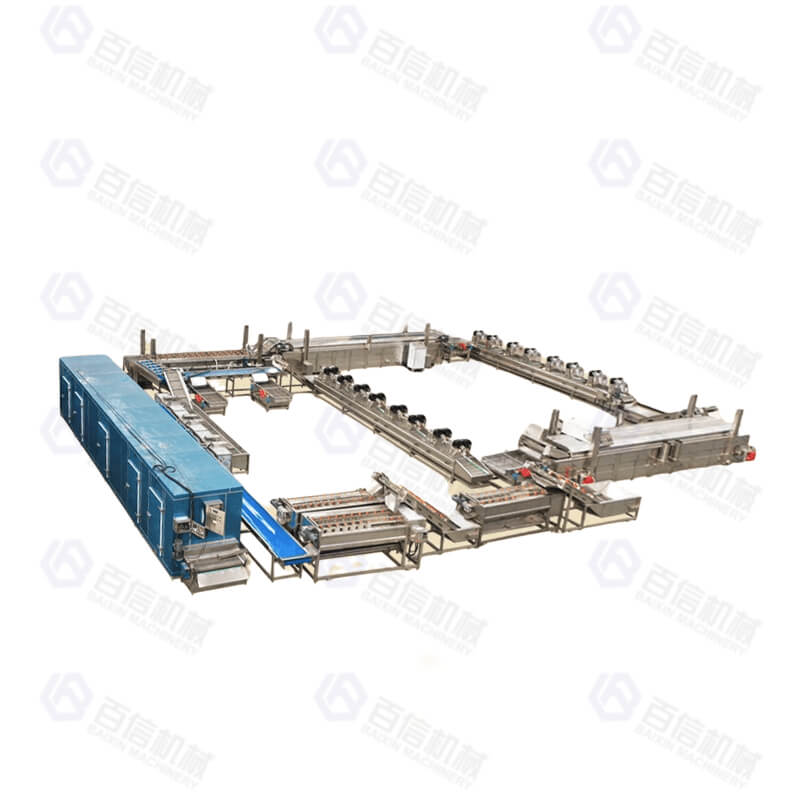

French Fries Production Line Process Flow

Fresh raw potato—Pre-washing and sinking stone—Peeling and washing—Manually picking —Slicing—Pre-washing strips—Tiny strips removing—Strips washing the starch—Strips hot water blanching—Water cooling—Vibrating remove water—Air dryer dewatering—Hot air drying—Hot oil frying—Vibrating remove oil—Air drying deoiling—Pre-cooling—Quick freezing—Weighing and packing—Metal detection—Bag organization—Box packing and sealing

Potato Raw Material and Finished French Fries Standards

To ensure consistent quality and good taste of French fries, and to improve yield and consistency throughout the production process, strict control must be implemented from raw material selection to finished product standards. The following summarizes the requirements for potato raw materials suitable for French fries processing and the core quality indicators of finished French fries, which can serve as an important reference for production and procurement.

Potato Variety Recommendation:

Shape: The tubers are oblong, large and uniform, with smooth skin and shallow eyes.

Color: Both the skin and flesh of the potato are white.

Size: 60-80mm. Starch content in the tuber: 15%~17%. Reducing sugar content: less than 0.2%.

Finished French Fries Standards

Appearance: The color is a uniform pale yellow to golden yellow, with no excessive frost on the surface.

Texture: After being fried or heated, the outer skin is crispy and the inside is soft and fluffy.

Moisture content controlled at ≤65%. Starch content between 14% and 17%. Reducing sugar content ≤0.25%.

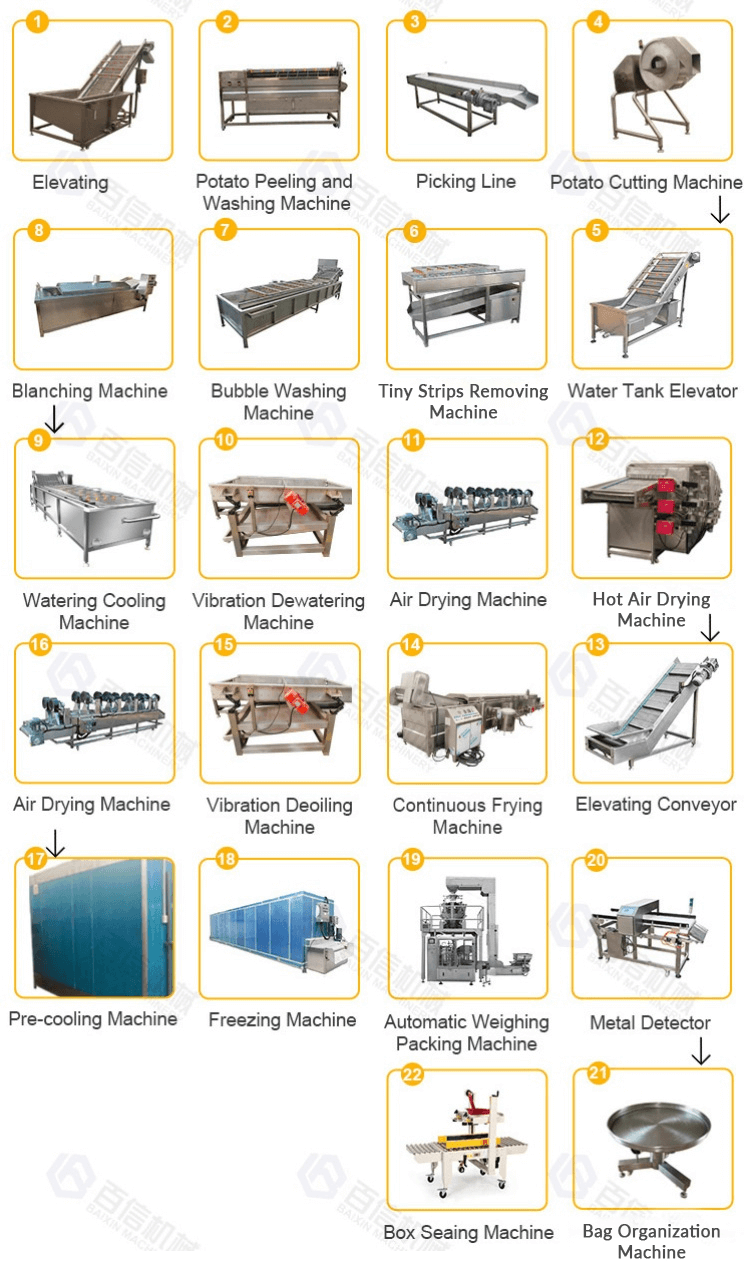

Introduction to Core Equipment of French fries production line

Understanding the complete process flow, you can see that a complete french fries production line consists of multiple stages and multiple machines . From raw material pretreatment to final packaging, each piece of equipment undertakes a specific processing task to ensure that the overall process is continuous, efficient and standardized.

1.Sinking stone elevator

Effective separation of impurities ensures that potatoes entering subsequent processing stages are free of heavy impurities that could damage the equipment, such as stones and clods of soil, thus guaranteeing the normal operation of the equipment and product quality.

2.Screwpeeling and washing machine

The spiral and brush roller effectively remove the potato skin during rotation and wash the potatoes using the rinsing action of water.

3.French fries cutting machine

Cut the peeled potatoes into fries according to the preset size specifications. Sizes such as 7*7 mm, 8*8 mm, 10*10 mm, 12 * 12 mm , and custom sizes can all be changed by adjusting the blade.

4.Water bucket elevator

Wash and remove the starch from the surface of the potatoes to reduce their contact with air, prevent oxidation and blackening , and transport the potatoes to the next process.

5.Short strip removal machine

Remove substandard and shorter fries. This machine can process large quantities of fries in a short time, and the screening and cleaning functions can be performed simultaneously. The standard gap between the bristle rollers is 4mm, but customization is available.

6.Bubble cleaning machine

The bubble washing machine uses the agitation of bubbles to tumble the fries in the washing tank, effectively removing impurities and starch, keeping the fries clean and preventing them from sticking together.

7.Blanching machine

Treating the fries with hot water at 60-95 degrees Celsius deactivates the enzymes, thus preventing color changes during subsequent processing and storage.

By altering the internal cell structure of French fries, they become crispier and have a better texture.

8.Water cooling machine

Quickly immerse the blanched fries in cold water to cool them down, altering their internal physical structure and improving their texture.

9.Air drying machine

Further and quickly remove moisture from the surface of the fries.

Continuous frying machines can quickly fry French fries in cooking oil at a high temperature of 160-180℃ for 30-40 seconds, giving the fries the ideal taste and texture.

11.Vibratory deoiling machine

Vibrating oil drainers can quickly remove oil from the surface of French fries. They use vibration to significantly reduce the oil content of French fries in a short time.

Quickly remove the oil from the surface of the French fries.

12.Air drying machine

Quickly removes oil from the surface of French fries.

Based on fluidization technology, the fan forms a high-speed airflow through the cold air. When the airflow passes through the French fries from bottom to top, the French fries are blown up by the airflow and present a state similar to boiling liquid, that is, fluidization. In this state, the French fries are fully in contact with the cold air and are quickly frozen.14.Automatic weighing and packaging machine

14.Automatic weighing and packing machine

French fries packaging machines can package French fries according to preset weights or quantities.

Guide to Selecting a French Fries Production Line

The above content has systematically introduced the core equipment, process flow, and quality requirements of a french fries production line . However, in actual production, key issues such as equipment footprint, factory conditions, energy consumption, and labor costs also need to be considered . Based on different production capacity needs and investment budgets, Baixin Machinery has launched three targeted purchasing options.

1.Small-scale processing capacity (50kg/h–100kg/h)

Features and advantages:

Small-scale french fries production line s require little space, have low investment costs, and are easy to operate. Employees can operate them independently after short-term training, making them ideal for start-ups or small-scale investors. The entire process is intuitive, with low financial pressure, quick start-up, short payback period, and high cost-effectiveness.

Construction conditions and resource requirements:

The requirements for the factory building are not high. It is necessary to have a flat ground that is easy to clean and maintain good ventilation. Basic electricity and water supply can meet the production needs. The equipment investment is approximately $ 20,000–50,000. The water consumption per shift is 500–800L, and the electricity consumption is 20–180kW (depending on the heat source). Only 3–5 operators are required .

2.Medium-sized processing capacity (200kg/h-400kg/h)

Features and Advantages:

Medium-capacity french fries production line s have a significantly higher level of automation than small-scale equipment, enabling continuous and stable production. Balancing efficiency and cost, they eliminate the need for the high investment and complex control required for large-scale production lines, while significantly improving processing efficiency and reducing reliance on manual labor, making them ideal for investors looking to expand production capacity.

Construction conditions and resource requirements:

This production line occupies approximately 300 square meters, with relatively moderate requirements for the plant: a flat, hardened ground, stable power supply, and sewage disposal capacity, while ensuring sufficient space for equipment installation, ease of operation, and food safety conditions to guarantee efficient and stable operation. The total investment for the entire set of equipment is approximately $70,000–200,000. Each shift consumes 1000–1500L of water and 50–350kW of electricity (depending on the heat source). Production can be completed by 2–4 operators.

3.Large-scale processing capacity (500kg/h–1000kg/h)

Features and Advantages:

This type of french fries production line enables fully automated and continuous production from potato raw materials to finished products, making it suitable for large-scale food processing plants. The high degree of automation significantly reduces labor costs, boasts high energy efficiency, and its oil circulation and filtration system effectively minimizes oil loss. This results in low unit production costs, stable finished product quality that meets export and industry standards, making it the top choice for companies seeking high efficiency and reliability.

Construction Conditions and Resource Requirements:

Large-scale french fries production line s have high requirements for factory buildings and infrastructure, with sufficient space reserved for raw material storage, temporary storage of finished products, and equipment maintenance access to ensure convenient and safe operation . The area required is approximately 500–750 square meters. The factory building needs a stable power supply to ensure the efficient operation of the entire production line; a sufficient and stable water source, including process water and domestic water, to meet the needs of washing, blanching, and cooling processes; and a complete drainage and wastewater treatment system . A large-scale french fries production line consumes approximately 2500–3500L of water and 200–1000kW of electricity per day (depending on the heat source), requires 4–6 operators, and has a total investment of approximately $280,000–450,000.

How to Choose a Suitable French Fries Production Line

A suitable french fries production line can significantly improve processing efficiency, effectively reduce energy consumption and labor input, minimize unnecessary resource waste, and create greater value for the long-term operation of a business. To help investors make more informed decisions, Baixin Machinery, based on years of project experience, has summarized three key recommendations :

1.Define production requirements and budget

Before selecting a french fries production line , the target output and overall budget should be determined first, as this forms the basis for all configuration planning. Different factories have significantly different production scales, ranging from small production lines producing tens of kilograms per hour to large industrial production lines producing several tons per hour. The required equipment specifications, number of machines, level of automation, and investment costs will vary considerably. Only by clearly defining the production volume, finished product specifications, and investment ceiling can a reasonable configuration plan be developed, avoiding order disruptions due to insufficient capacity and unnecessary investment caused by blindly pursuing high configurations .

2.Consider factory space

The floor space required for french fries production line s varies significantly depending on their capacity . Therefore , before purchasing equipment, a comprehensive assessment should be conducted based on the factory's actual area , construction conditions, budget, and production capacity. First, ensure the factory space can accommodate the target capacity of the french fries production line and guarantee a smooth processing flow. From raw material intake, washing and cutting, blanching and frying to cooling, quick-freezing, and packaging, a straight or U-shaped streamlined layout should be implemented . Secondly, areas for raw material storage, personnel movement, and offices should also be reserved . Communicating with the french fries production line manufacturer to customize a layout plan is particularly important. Baixin Machinery can provide professional equipment layouts based on factory dimensions , ensuring the production line truly matches the site environment and achieves more efficient production flow.

3.Focus on equipment quality and the manufacturer's overall strength

Equipment quality and manufacturer strength are core factors determining the stability and lifespan of a production line . When selecting a french fries production line manufacturer , investors should focus on understanding the manufacturer 's production process level, number of project cases, after-sales service scope (installation, transportation, and after-sales) , and whether they have customized design capabilities. They should also pay close attention to details such as the machine's materials, energy consumption indicators, and automatic control system. Below are Baixin Machinery's specific advantages in these areas.

- Baixin Machinery will dispatch professional engineers to the site for installation and commissioning to ensure the smooth operation of the production line, and will also provide operation and maintenance training.

- Regarding transportation, Baixin Machinery has extensive export experience and standardized transportation procedures to ensure that equipment is delivered to the customer's site safely and quickly.

- We offer a one-year warranty, 24-hour response during production line operation, and repair or free replacement within 7 days for equipment damaged due to quality issues.

A french fries production line enables the industrialization, scaling, and standardization of french fries production. Choosing efficient and reliable equipment not only ensures quality but also achieves production efficiency and cost control. A comprehensive understanding of the process, equipment, and key selection points can effectively reduce investment risks. Baixin Machinery, with its extensive experience, provides scientific configuration and technical support to help you start production smoothly . If you are also considering a french fries production line , please feel free to contact Baixin Machinery. We will assign a dedicated project manager to provide a customized complete solution based on your needs, free of charge .