Frozen French Fries Manufacturing Process

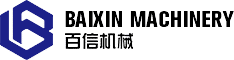

Frozen French Fries Production Process

Frozen French fries production involves a series of physical processing and low-temperature treatments to transform fresh potatoes into a semi-finished food product that can be frozen for extended periods and eaten after reheating. Its core advantage lies in using rapid freezing technology to lock in the potatoes' moisture and nutrients, preserving the crispy texture and natural flavor of the fries while extending their shelf life. The entire process follows these steps:

Fresh raw potato—Pre-washing and sinking stone—Peeling and washing—Manually picking —Slicing—Pre-washing strips—Tiny strips removing—Strips washing the starch—Strips hot water blanching—Water cooling—Vibrating remove water—Air dryer dewatering—Hot air drying—Hot oil frying—Vibrating remove oil—Air drying deoiling—Pre-cooling—Quick freezing—Weighing and packing—Metal detection—Bag organization—Box packing and sealing

Potato Raw Material and Finished French Fries Standards

Potato ingredient recommendations:

Shape: The tubers are oblong, large and uniform, with smooth skin and shallow eyes.

Color: Both the skin and flesh are white.

Size: 60-80mm. Starch content: 15%~17%.

Reducing sugar content: less than 0.2%.

Finished French Fries Standards:

Appearance: Uniform pale yellow to golden yellow color, with minimal frost on the surface.

Taste: After double-frying or heating, the outer layer is crispy, and the inside is soft and fluffy.

Moisture content: ≤65%.

Starch content: 14%-17%.

Reducing sugar content: ≤0.25%.

Overview of Frozen French Fries Production Process

The production process of frozen French fries has clear technical standards and operating procedures for each step. The following is a detailed introduction:

(1) Washing and Sorting

Washing: A drum washing machine is used to initially remove a large amount of dirt from the surface of the potatoes.

Sorting: A grading machine can separate potatoes into different grades according to standards such as diameter or volume, ensuring that the subsequent slicing process can produce fries of more uniform thickness, and ensuring more even heating during frying, thereby improving the taste and appearance quality of the fries.

(2)Washing and Peeling

The fully automatic quick-frozen French fries production line mainly uses a screw washing and peeling machine. During the rotation of the screw and brush roller, the outer skin of the potato is effectively removed, and then the potato is washed by the rinsing action of water.

(3)Strip Cutting

Peeled potatoes are fed into a high-efficiency slicing machine, which cuts them into strips of various sizes (7*7mm, 8*8mm, 10*10mm, etc., customizable) according to market demand. The slicing machine is equipped with high-precision blades to ensure uniform fry size and prevent broken or fragmented strips.

The sliced fries are immediately rinsed with bubble washing machine to remove surface free starch. If starch residue remains, the fries will stick together and burn during frying.

(4)Blanching and Pre-cooling

Blanching: Cut French fries are prone to oxidation and turning black, and their internal starch is easily retrograded, so blanching is necessary.

Place the fries in hot water at 60-95℃ to deactivate the enzymes in the fries, thus preventing color changes during subsequent processing and storage. Blanching also removes surface free starch, preventing sticking during later processing.

Pre-cooling: After blanching, the fries need to be quickly cooled to reduce nutrient loss and alter their internal physical structure, improving their texture.

(5)Dewatering and Drying

Cooled French fries retain a lot of moisture on their surface, which can affect product quality if they are fried or frozen directly. Therefore, dehydration equipment is needed to remove the surface moisture. First, a vibratory dehydrator uses high-frequency vibration to quickly separate the surface moisture, which is highly efficient. Then, a hot air dryer uses low-temperature hot air to dry the moisture, which can further stabilize the texture of the French fries.

(6)Pre-fried French Fries

Frozen fries require an additional pre-frying step. Dehydrated fries are quickly fried in edible vegetable oil at 160-180℃ for 30-40 seconds, creating a crispy outer shell while retaining some moisture inside. After pre-frying, the fries need to be degreased using an oil remover to remove excess oil.

(7)Pre-cooling and Quick-freezing

Pre-cooling: Rapid cooling prevents the fries from overcooking due to prolonged exposure to high temperatures, maintaining their ideal texture and color. Pre-cooling machine quickly lower the temperature of the fries to a level suitable for the next process, improving quick-freezing efficiency.

Quick-freezing: Quick-freezing is the core step in frozen fries production. Its purpose is to lower the core temperature of the fries to below -18°C in a short time, locking in moisture and nutrients.

Currently, tunnel-type quick-freezing machine are mainly used. The fries enter the quick-freezing tunnel via a conveyor belt and are rapidly frozen in a low-temperature environment of -35°C to -40°C. The freezing time is typically controlled within 15-30 minutes. Quick-frozen fries have a firm texture, and their taste after heating is minimally different from fresh fries.

(8)Automatic Weighing and Packing

Frozen French fries are automatically conveyed to a multi-head weighing and packaging machine, which packages the fries according to a preset weight or quantity. After packaging, the products are sent to a low-temperature cold storage for later sale.

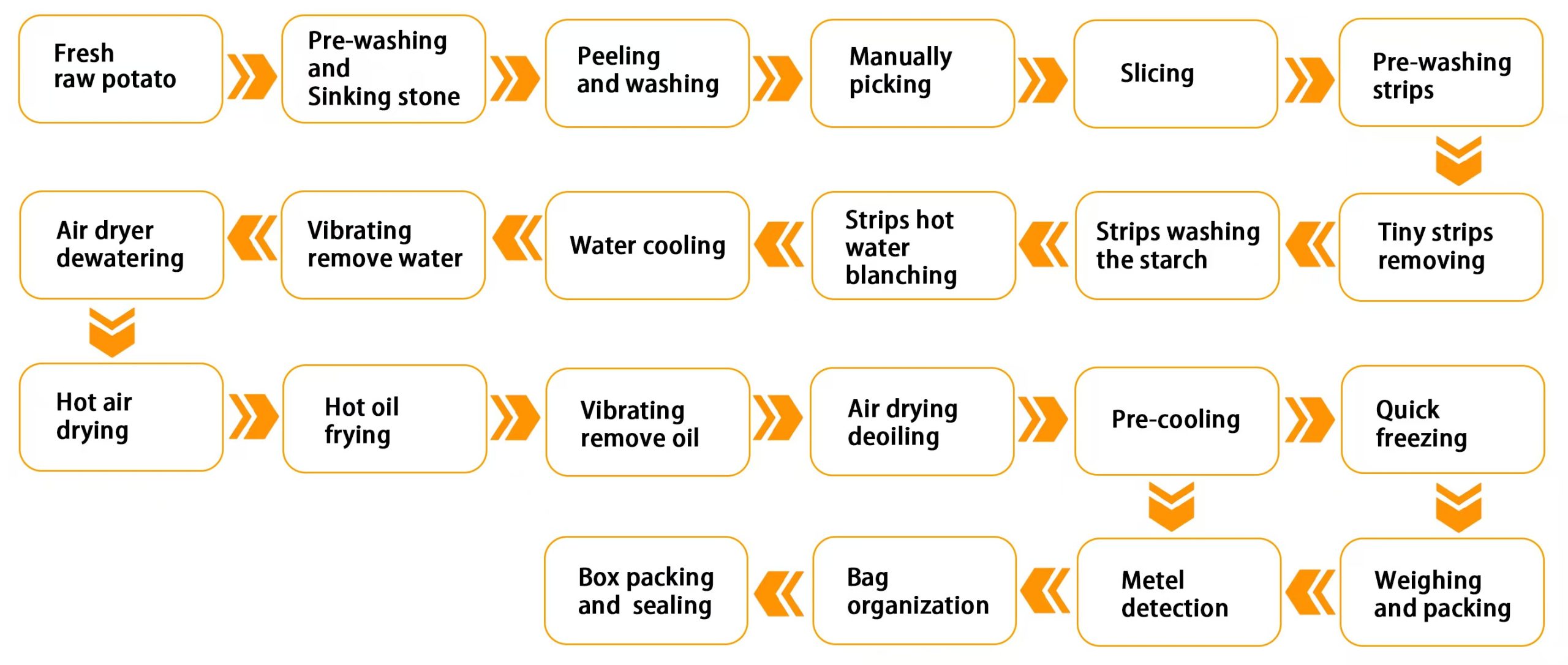

Introduction to Types and Advantages of Frozen French Fries Production Lines

After understanding the production process of frozen French fries, selecting the right processing equipment is crucial for efficient and stable processing. The market offers a wide variety of machines for frozen French fries production, each with its own characteristics in terms of capacity, automation level, and processing effect. Below are some common frozen French fries production lines with different processing capacities to help businesses choose the right model based on their production volume and process requirements.

1.Small-scale processing (50–100 kg/h)

Features and advantages: Small footprint, low investment, simple operation, short employee training period, suitable for start-ups or small-scale investors, quick start-up, and short payback period.

Construction conditions: Low factory requirements, basic electricity and water supply are sufficient, investment is approximately $20,000–50,000, water consumption per shift is 500–800L, electricity consumption is 20–180 kw(depends on the heat source), and 3–5 operators are required.

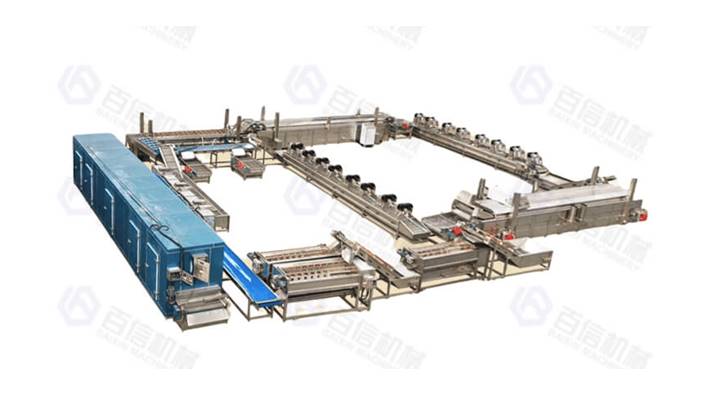

2.Medium-sized processing capacity (200–400 kg/h)

Features and advantages: High degree of automation, continuous and stable production, balancing efficiency and cost, suitable for capacity expansion.

Construction requirements: Approximately 300 square meters of land, requiring leveled plant, stable power supply, and sewage discharge capacity. Investment is approximately $70,000–200,000. Water consumption per shift is 1000–1500 L, power consumption is 50–350 kw(depends on the heat source), and 2–4 operators are required.

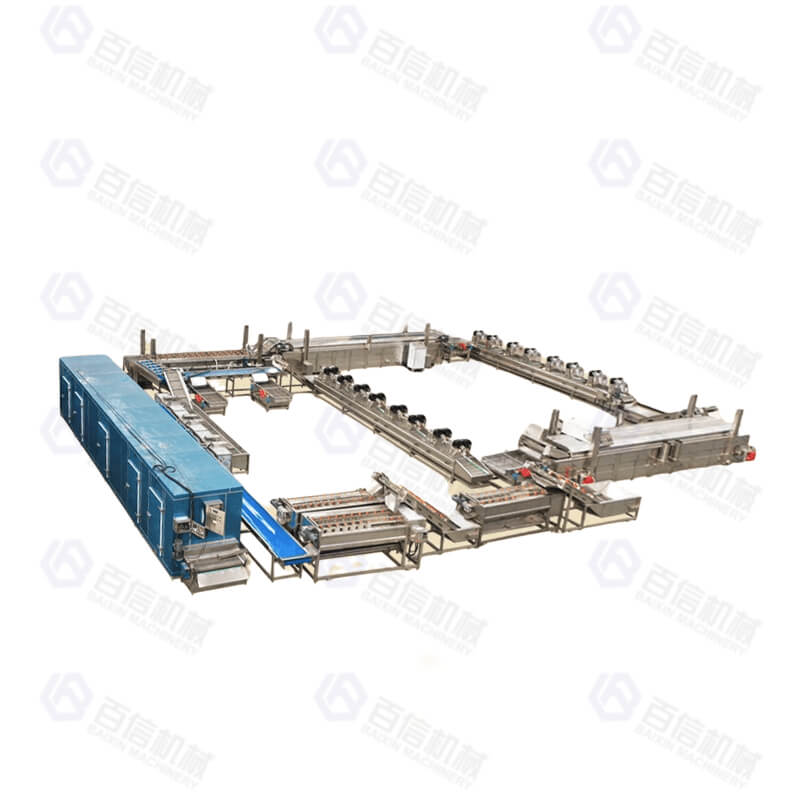

3.Large-scale processing capacity (500–1000 kg/h)

Features and advantages: Fully automated process, suitable for large processing plants, reduces labor costs, oil circulation system reduces losses, stable finished product quality, suitable for export standards.

Construction requirements: 500–750 square meters of land required; stable power supply, sufficient water supply, and proper drainage; investment approximately $280,000–450,000; water consumption per shift: 2500–3500 L; power consumption: 200–1000 kW(depends on the heat source); 4–6 operators required.

The production of frozen french fries involves a rigorous control chain from raw materials to finished product. Attention to detail in every step directly determines the product's taste, quality, and market competitiveness. If you require more professional advice regarding the frozen French fries production process and processing machinery, please feel free to contact us. Baixin will provide you with customized solutions.