Plantain Chips Machine

Plantain chips machines are complete production lines encompassing raw material pretreatment , blanching , washing, peeling , slicing, frying, deoiling, seasoning, and automatic packaging . They are widely used in snack food factories and export-oriented food companies. This article will systematically analyze aspects such as plantain raw material standards, finished product quality requirements, equipment configuration schemes for different production capacities, factory construction needs, investment costs, and manufacturer after-sales service. This will help investors quickly understand the core elements of plantain chips machine production projects and choose a suitable production line solution.

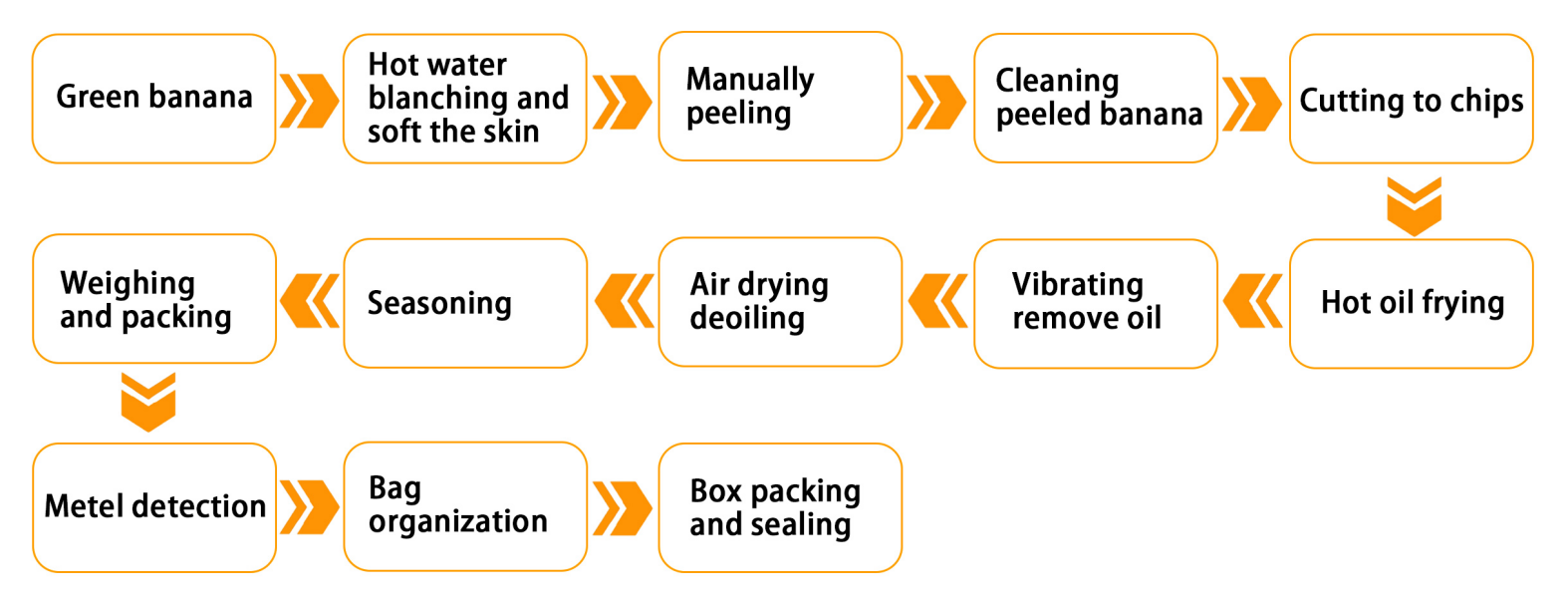

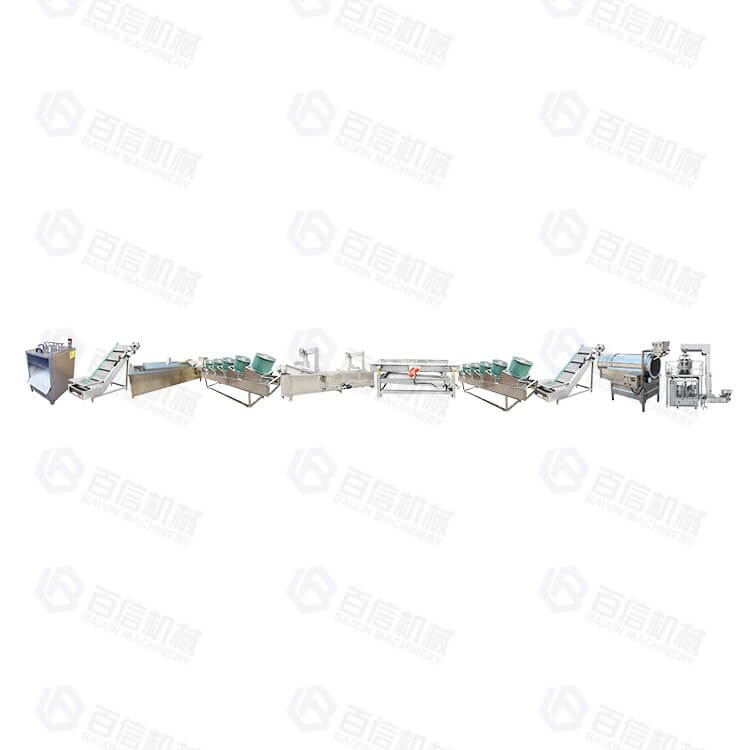

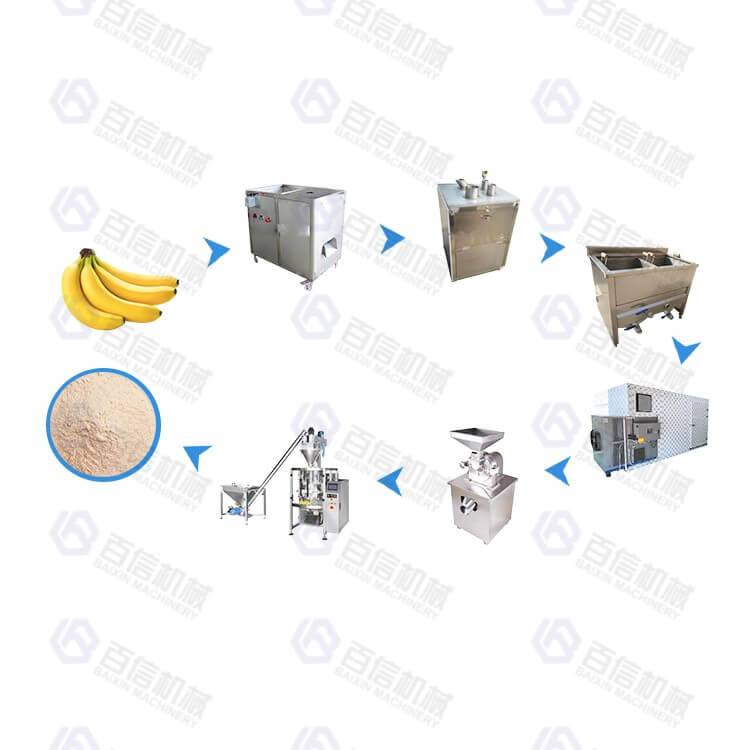

Plantain Chips Machines and Technology Flow

Understanding plantain chips machine is fundamental to starting a fried plantain chips business. To ensure that expected production capacity and product quality are achieved after production begins, a thorough understanding of the processing flow is also necessary. A common plantain chips machine processing flow is as follows:

Green banana-Hot water blanching and soft the skin-Manually peeling-Cleaning peeled banana-Cutting to chips-Hot oil frying-Vibrating remove oil-Air drying deoiling-Seasoning-Weighing and packing-metal detection-Bag organization-Box packing and sealing

Standards for Plantain Raw Materials and Finished Plantain Chips

The quality of raw materials directly affects the slicing rate, frying color, and final crispness of plantain chips machines. Simultaneously, the finished product must meet specific requirements for color, crispness, and moisture content to ensure competitiveness in the market. Therefore, Baixin Machinery will explain the selection criteria for raw materials and the quality requirements for finished products, providing a reference for manufacturing enterprises.

Standards for selecting plantainraw materials

Shape: Long and narrow, uniform in size, making it easy to slice.

Cooking level: 50%-70% (leaning towards green) is recommended for a crispier result after frying.

Appearance: Smooth surface, free of mold and black spots.

Firmness: Firm, green bananas ensure that the slices remain intact.

Quality requirements of finished products

Appearance: Golden in color, intact in shape, and without excessive burning.

Texture: Crispy, not greasy, and without any bitterness.

Oil content: around 20 % is optimal.

Sheet thickness: 1.5 – 2.0 mm

Flavor: Evenly seasoned, with no rancid oil taste.

How to choose plantain chips machine?

After clarifying the process requirements and finished product standards for banana chips, investors also need to comprehensively consider processing capacity, budget, factory conditions, and energy consumption when selecting machinery. Different sizes of plantain chips machines vary significantly in terms of automation level, configuration, construction conditions, and operating costs. Below, Baixin will provide selection options for plantain chips machines based on three capacity categories: small, medium, and large.

1.Small-scale processing capacity (50kg/h)

Features: Small-scale plantain chips machines are suitable for investors with low capacity requirements who want to quickly establish and start production, achieving good processing efficiency while controlling procurement costs. The biggest advantages of this production line are low investment risk, low start-up costs, and a short payback period, making it ideal for market testing or regional brand trial production.

Configuration: Manual peeler - slicing machine - batch frying machine - deoiling machine- seasoning machine - packing machine

Project resource requirements : There are no high requirements in terms of land area, operational difficulty, or initial investment. The entire production line generally requires only 120 square meters of space. Water, electricity, and drainage conditions are also not complicated, and ordinary factory buildings can basically meet the needs. The cost of this equipment is approximately US$50,000-60,000. Each shift consumes approximately 300-500 liters of water and 60-100 kilowatts of electricity (depending on the heat source). It requires 3-5 operators.

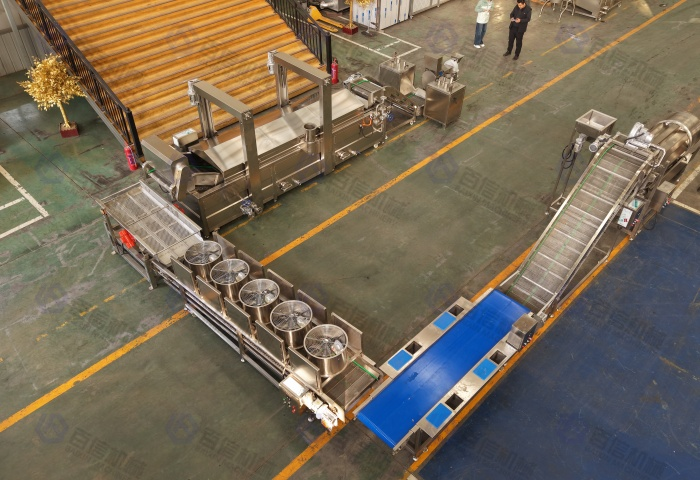

2.Medium-sized processing capacity (100kg/h–200kg/h)

Features: Medium-sized plantain chips machine are currently one of the most favored production capacity ranges for food companies. They combine increased automation, reasonable investment, stable production capacity, and suitability for long-term operation. Unlike large-scale production lines, they do not require the huge investment required, yet achieve a good balance between efficiency, quality control, and economies of scale. This makes them ideal for regional wholesalers, food brand factories, and companies supplying chain supermarkets. These production lines are suitable for companies looking to expand production, stabilize supply, and enhance brand competitiveness.

Configuration: Raw materials - manual peeling - slicer - elevator - continuous fryer (equipped with vacuum oil filter and oil adder) - vibrating deoiling - elevator - seasoning machine - packing machine

Project Resource Requirements : Medium-sized plantain chips production lines have relatively higher requirements for factory conditions. They not only need sufficient space for equipment layout, logistics flow, and temporary storage of finished products, but also require floors with good load-bearing and drainage capabilities, and stable power and water supply systems to support the simultaneous operation of multiple stages such as blanching, frying, and cooling. Although automation is improved, medium-sized production lines still retain some manual processes, but the overall number of workers is significantly reduced compared to small production lines, and daily management and maintenance are more systematic. The entire production line requires a floor area of 350-750 square meters, with an investment cost of approximately US$90,000-160,000. Each shift consumes approximately 1500L-3500L of water and 200-400KW of electricity (depending on the heat source), requiring 2-4 operators.

3.Large-scale processing capacity (200kg/h–300kg/h)

Features: Large-scale plantain chips machine production lines can operate continuously around the clock, with production efficiency far exceeding that of small and medium-sized lines. They maintain stable production capacity during extended operation, significantly reducing reliance on manual labor. A sophisticated oil circulation and automatic oil filtration system ensures more consistent oil quality, improving product color and taste while effectively reducing long-term oil consumption costs . For companies requiring a stable supply to large supermarkets, restaurant chains, or export orders, large-scale production lines are the most reliable choice.

Configuration: Raw material sorting table - bubble washing machine - blanching machine - water cooling- air dryer - manual peeling - slicing machine - elevator - continuous fryer (equipped with vacuum oil filter and oil adder) - vibrating deoiling machine - air dryer - finished product sorting - seasoning machine - packing machine

Project Resource Requirements : The planning of a large-scale plantain chips machine production line requires careful consideration of equipment layout, logistics routes, raw material and finished product storage areas, and ventilation and oil drainage systems. Furthermore , the production line has high requirements for the stability of electricity and water supply, necessitating a sufficient capacity power supply, a reliable water supply system, and efficient drainage and oil drainage facilities to meet the cleaning, blanching, and cooling needs during continuous production. Generally, approximately 1000 square meters of factory space is needed to accommodate multiple high-volume plantain chips machines for continuous washing, slicing, blanching, frying, oil removal, seasoning, and automatic packaging . This type of production line consumes approximately 4000-5500L of water and 400-500kw of electricity per shift (depending on the heat source), requires 3-4 operators , and has a total investment cost of approximately US$200,000.

The Strength of Potato Chips Machine Manufacturers

To ensure the smooth commissioning and operation of a potato chip processing project, investors need to pay attention not only to the price of the processing machines but also to the manufacturer's guarantees in installation, commissioning, logistics, and warranty services. Baixin Machinery provides a systematic after-sales service standard for these key aspects to ensure the smooth implementation and long-term stable operation of the customer's production line.

Installation: For projects requiring installation, Baixin Machinery will arrange an experienced engineering team to carry out the installation work on-site and conduct comprehensive trial runs after installation to ensure smooth production line operation. In addition, engineers will provide training to operators on equipment use and maintenance, helping customers to quickly start production and operate worry-free.

|

Install Details |

|

|

1 |

Our company attaches great importance to installation. We have our own installation team. The number of installation personnel has grown from the initial 3 to a current team of 10, and we are still training more people. |

|

2 |

The majority of our equipment upgrades come from the installation site. This is the core aspect through which we ensure the equipment is up-to-date and employs the latest processing techniques. |

|

3 |

Our installation team has installation experience in over 20 countries. Our company encourages business personnel to participate in the on-site installation together with the installation team, providing more professional and high-quality after-sales service. |

|

4 |

After each installation site is completed, our after-sales department, technical department, production department and business department will organize special seminars to ensure that our after-sales service capabilities and equipment quality keep improving. |

|

5 |

After the equipment is delivered, we will provide a list of installation tools that need to be prepared on-site, a material list, and other necessary preparations. |

|

6 |

During the on-site installation process, we will provide training services, including operation of the production line and daily maintenance. |

Delivery: Baixin Machinery has many years of export experience and has formed a complete and standardized equipment transportation process, which can ensure that each batch of machines is delivered to the customer's site safely, efficiently and accurately.

|

Delivery Steps |

|

|

1 |

The production department, the after-sales department and the business department will check the delivery list one by one to ensure that no details are missed. |

|

2 |

Equipment container planning, providing the most optimal container arrangement plan to ensure the safety of equipment loading, with the minimum number of containers required. |

|

3 |

Establish an order delivery group, and assign a specific person for each batch of goods. Conduct a re-count of the equipment. |

|

4 |

During the shipping process, photos of each device and component are taken for record-keeping. |

|

5 |

After the goods are dispatched, provide the customers with detailed and accurate packing information to make the receiving process as smooth as possible for them. |

|

6 |

During the shipping process, photos of each device and component are taken for record-keeping. |

Warranty:We offer a one-year warranty on all equipment and maintain a 24/7 online response mechanism during production line operation to ensure timely resolution of any issues. For malfunctions caused by defects in the equipment itself or the manufacturing process, Baixin Machinery will provide repair or free replacement services within 7 days of purchase.

|

Warranty |

|

|

12 months |

Seller warrants that the Equipment supplied shall be new and shall be free from defects in materials and workmanship for period of 12 months from the date of commissioning and handover of the complete working plant by Seller to Buyer the "Warranty Period"). |

|

7days |

Seller's warranty covers the following:Defects in materials and workmanship of the Equipment.Any defective parts (due to defects in materials and workmanship during the warranty shall be repaired /replaced free of cost within 7days free of cost. |

|

24h |

During the operation of the production line, if any problems arise, we offer 24-hour online prompt responses. |

In summary, potato chips machine price in Ethiopia fluctuates significantly. Therefore, before investing, companies need to conduct a comprehensive evaluation based on their own production capacity needs, market positioning standards, factory conditions, and equipment quality. Choosing a reliable supplier is crucial. Baixin Machinery, with its high-quality equipment, advanced technology, and comprehensive installation, commissioning, and after-sales service, can provide professional support to potato chip production companies of all sizes. If you are planning to invest in a potato chip processing project, please contact Baixin Machinery. We will assign a professional project manager to provide you with a customized solution.